Ho otlolla li-castings, tse tsejoang hape e le tokiso kapa tokiso, ke mohato oa bohlokoa ts'ebetsong ea tlhahiso ho netefatsa hore likarolo tsa tšepe li kopana le litlhaloso tse nepahetseng tsa sebopeho le bots'epehi ba sebopeho.

Mekhoa ea ho Otlolla

Ho na le mekhoa e 'maloa e sebelisoang ho otlolla li-castings, e' ngoe le e 'ngoe e loketse mefuta e fapaneng ea thepa le libopeho tsa ho lahla. Mekhoa ea pele e kenyelletsa:

Ho otlolla Mechini: Sena se kenyelletsa ts'ebeliso ea matla a kantle ho sebelisoa lisebelisoa tsa mochini le mechini. Mekhoa e kang ho tobetsa, ho kobeha le ho otla ka hamore e tloaelehile. Ho otlolla mechine ho sebetsa ka ho khetheha bakeng sa li-castings tse kholo le tse tiileng.

Ho otlolla Mocheso: Ka mokhoa ona, mocheso o sebelisoa libakeng tse itseng tsa ho lahla ho etsa hore ho be le ho atolosoa ha mocheso kapa ho fokotseha, kahoo ho lokisa ho khopama. Mokhoa ona o molemo bakeng sa li-castings tse ka senyehang habonolo kapa ho robeha tlas'a khatello ea mochine.

Ho otlolla ha Hydraulic: Ho sebelisa mechine ea khatiso ea hydraulic, mokhoa ona o sebetsa khatello e laoloang ho otlolla li-castings. E fana ka ho nepahala ho phahameng 'me e loketse libopeho tse bonolo le tse rarahaneng tse hlokang ho tšoaroa ka hloko.

Mekhoa ea ho Kopanya: Hangata, motsoako oa ho otlolla ha mochini le mocheso o sebelisoa ho fihlela sephetho se lakatsehang, haholo-holo ho li-castings tse nang le li-geometri tse rarahaneng le thepa e fapaneng ea thepa.

Tlhophiso le Khetho ea Lisebelisoa tsa ho Otlolla

Khetho ea lisebelisoa tsa ho otlolla e itšetlehile ka lintlha tse 'maloa, ho kenyelletsa le mofuta oa ho lahla, thepa ea thepa, le boholo ba deformation. Mefuta e ka sehloohong ea lisebelisoa ke:

Lisebelisoa tsa ho otlolla ka letsoho: Lisebelisoa tse bonolo tse kang lihamore, li-anvils, le mechine ea khatiso e tšoaroang ka letsoho li sebelisoa bakeng sa litokiso tse nyenyane kapa tse nyenyane. Ba hloka basebetsi ba nang le litsebo ho fumana liphetho tse nepahetseng.

Likhatiso tsa Mechini: Tsena li kenyelletsa li-toggle presses, screw presses, le eccentric presses. Li loketse li-castings tse mahareng ho isa ho tse kholo mme li fana ka ts'ebeliso ea matla e tsitsitseng. Mechine ea khatiso ea mechine e khethoa bakeng sa ho tšepahala le boiketlo ba ho sebetsa.

Likhatiso tsa Hydraulic: Mekhatiso ena e fana ka bokhoni bo phahameng ba matla le taolo e nepahetseng holim'a ts'ebeliso ea khatello. Li loketse ho otlolla li-casting tse kholo, tse boima le tse rarahaneng. Mechini ea khatiso ea Hydraulic e ka kengoa li-dies le li-fixtures tse fapaneng ho amohela libopeho le boholo bo fapaneng.

Libōpi tsa Phekolo ea Mocheso: E sebelisoa ho otlolla mocheso, libopi tsena li lumella ho futhumatsa ho laoloang ha li-castings ho etsa hore ho be le khatello ea kelello le ho lokisoa ha li-deformation. Li bohlokoa bakeng sa li-castings tse ke keng tsa mamella matla a mechine.

Ho otlolla Hoa Shoa

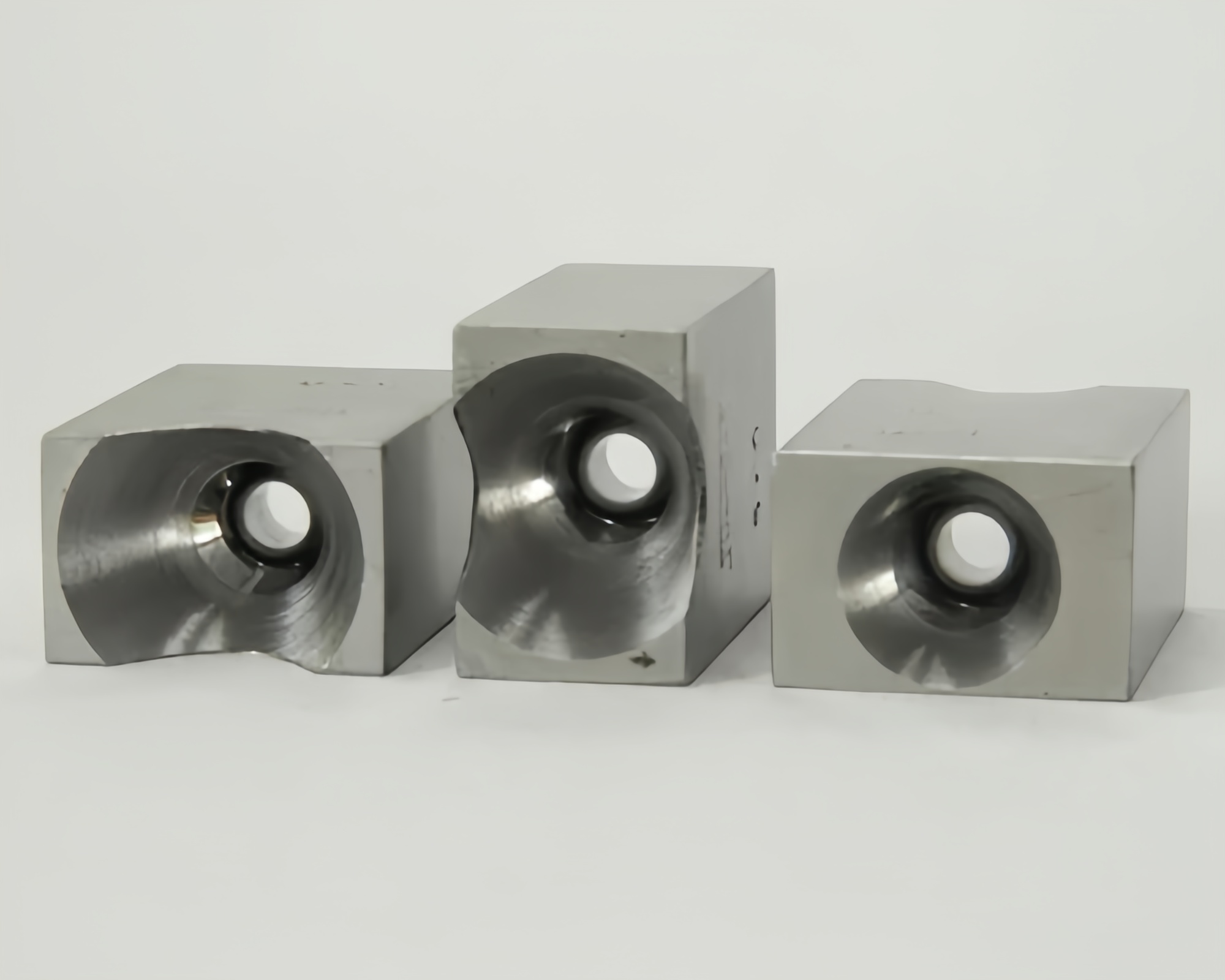

Straightening dies, eo hape e tsejoang e le correction dies, ke lisebelisoa tse entsoeng ka ho khetheha tse sebelisoang hammoho le mechine ea khatiso ho fetola ka nepo li-castings tse holofetseng. Li arotsoe ho latela ts'ebetso ea tsona le mofuta oa ho lahla tseo li sebelisetsoang:

Flat E shoa: Tsena li sebelisetsoa ho otlolla libaka tse bataletseng le mathōko. Li bonolo ka moralo empa li sebetsa hantle bakeng sa ho lokisa liphoso tsa moralo.

Ho theha E-shoa: E etselitsoe ho tsamaisana le contour ea casting, li-dies tsena li sebelisetsoa ho lokisa libopeho le li-curve tse rarahaneng. Li entsoe ka mokhoa o ikhethileng bakeng sa meralo e khethehileng ea ho lahla le ho netefatsa ho nepahala ha ho otloloha.

Tšehetso ea Shoa: Tsena li shoa li fana ka ts'ehetso le botsitso ho ho lahla nakong ea ts'ebetso ea ho otlolla. Li bohlokoa ho thibela ho senyeha kapa ho senyeha ho eketsehileng nakong ea khalemelo.

Khetho ea ho otlolla lefu e bohlokoa ho fihlela sephetho se lakatsehang. E tlameha ho lumellana le sebopeho's geometry le mofuta oa ho sotha ho fana ka khalemelo e sebetsang ntle le ho baka khatello e eketsehileng kapa tšenyo.

Ho otlolla li-castings ke ts'ebetso ea bohlokoa ho netefatsa boleng le ts'ebetso ea likarolo tsa tšepe. Ka ho sebelisa mekhoa e nepahetseng, ho khetha lisebelisoa tse nepahetseng, le ho sebelisa mokhoa o nepahetseng oa ho otlolla, bahlahisi ba ka lokisa mefokolo le ho hlahisa li-castings tse fihlelang litekanyetso tse nepahetseng. Sena ha se matlafatse ts'ebetso ea sehlahisoa sa ho qetela feela empa hape se lelefatsa bophelo ba ts'ebeletso ea sona, ho netefatsa ts'epo le khotsofalo ea bareki.

Nako ea poso: Oct-18-2024