Ho RMC Foundry, re sebelisa mekhoa e mengata ea ho lahlela lisebelisoa tsa tšepe le lisebelisoa ho latela litlhoko tsa moreki kapa ho ipapisitse le nts'etsopele ea rona. Mefuta e fapaneng ea tšepe le alloy e loketse ts'ebetso ea eona e ntle ka ho fetisisa ea li-castings ho nahanoa ka litlhoko tsa mosebelisi oa ho qetela le litšenyehelo tse sebetsang. Ka mohlala, thetšepe e entsoeng ka bohloohohangata e loketse ho lahleloa kemokhoa oa ho lahla lehlabathe, ha a ntse ats'epe e sa beng le mabalie atisa ho lahleloa ke ho lahleheloa ke boka ba lichelete tsa lichelete.

Ho na le lintlha tse ngata tseo re lokelang ho li ela hloko ha re khetha mekhoa e nepahetseng ea ho lahla, joalo ka ho lahleha ha thepa, tlhokahalo ea boima ba 'mele (Li-alloys tsa Aluminium le Zinc li bobebe ho feta lisebelisoa tse ling), thepa ea mochine le haeba ho na le ts'ebetso e khethehileng e hlokahalang. apare resistance, corrosion resistance, damping... etc. Haeba re khetha khethoho etsa ka nepo(hangata e bua ka tlhahiso ea matsete), ho tla ba le tlhokahalo e fokolang kapa e se nang lethomachining, e neng e ka boloka litšenyehelo tsohle tsa tlhahiso haholo.

Ka lebaka la boiphihlelo ba rona bo ruileng le lisebelisoa tse hlophisitsoeng hantle, re na le likhetho tse fapaneng tsalihlahisoa bakeng sa liindasteri tse fapaneng. Seo re se khethang haholo ke ho lahla lehlabathe, ho etsa matsete, ho akhela hlobo ea likhetla,foam e lahlehileng, vacuum casting le mochini oa CNC. Ka bobeli litšebeletso tsa tloaelo tsa OEM le R&D e ikemetseng li fumaneha fekthering ea rona. Boenjiniere ba profeshenale ke tlholisano ea rona ea mantlha.

Mefuta e fetang 100 ea tšepe le li-alloys e lahleloa setsing sa rona sa motheo. Haholo-holo ke mefuta e mengata ea tšepe e bohlooho,tšepe e entsoeng ka ductile, tšepe e entsoeng ka tšepe e bonolo ho ea ho tšepe ea carbon,tšepe ea motsoako, tšepe e sa hloekang le aluminium le lisebelisoa tsa koporo. Ka hona, ho tsoa ts'ebeletso ea rona, ka bobeli le ka khetha mokhoa o nepahetseng oa ho lahla le lisebelisoa ho fihlela kopo ea hau ea tlhompho. Ba bangata ba ronalikarolo tse tloaelehileng tsa ho lahlaba sebeletsa mefuta e mengata e fapaneng ea balekane ba mechini le liindasteri ho tsoa Europe, Amerika, Asia, Australia le ehlile, Chaena.

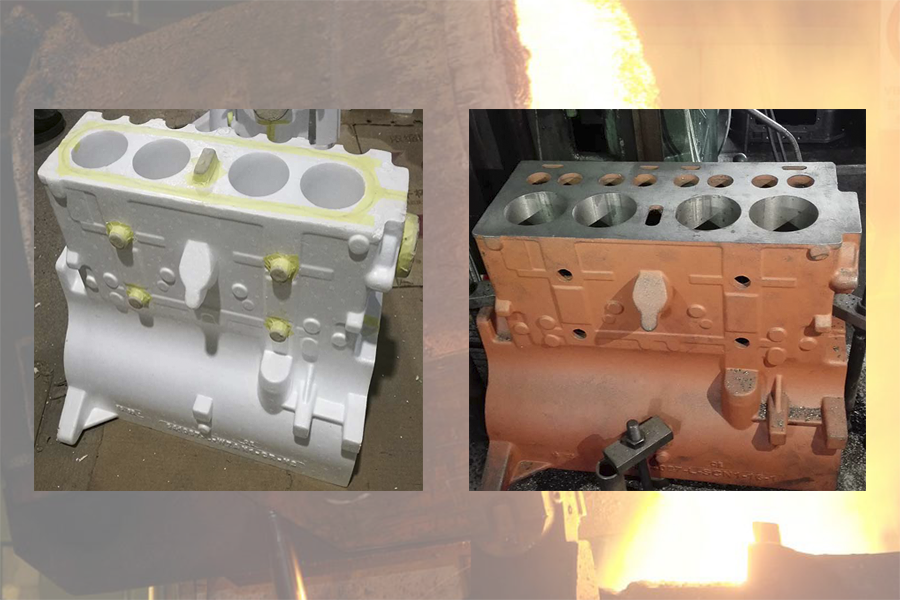

Li-casting tsa lehlabathe li nka boima bo boholo ka bongata lits'ebetsong tsohle tsa ho lahla. Tšepe e bohlooho, tšepe ea ductile, koporo, tšepe le aluminium ke lisebelisoa tse ka sehloohong tse entsoeng ka tšepe.

E boetse e bitsoa "lahleha oax casting" kapa "precision casting", ts'ebetso ea matsete e fihla ho nepahala ha maemo a geometrical le a dimension tolerances.

Ho hlahisa hlobo ea likhetla ho sebelisa lehlabathe le koahetsoeng esale pele ho etsa hlobo. E ka etsa li-castings tse betere ka holimo le ka boholo ho feta ho lahlela lehlabathe.

Lost foam casting, eo hape e bitsoang ho lahla hlobo e felletseng kapa ho lahla hlobo e se nang cavity, e phetha karolo ea bohlokoa ho lihatsetsi tse kholo le tse teteaneng tsa lebota.

Vacuum casting e boetse e bitsoa s V process cast casting, mold e tiisitsoeng kapa khatello e mpe. Ho khethoa lihlahisoa tse kholo le tse teteaneng tsa marako.

Bakeng sa likarolo tse ling tsa tšepe tse nepahetseng, CNC precision machining ke ts'ebetso e batlang e ka qojoa ka mor'a hore ho fumanoe li-castings tse felileng.

| Bokhoni ba ho Lahlela ho RMC Foundry | ||||||

| Mokhoa oa ho Lahlela | Bokhoni ba Selemo / Lithane | Lisebelisoa tse ka Sehloohong | Boima ba ho lahla | Kereiti ea Mamello ea Dimensional ea Castings (ISO 8062) | Kalafo ea Mocheso | |

| Ho Lahlela Lehlabathe le Letala | 6000 | Cast Grey Iron, Cast Ductile Iron, Cast Aluminium, Brass, Cast Steel, Stainless Steel | 0.3 lik'hilograma ho 200 lik'hilograma | CT11~CT14 | Ho tloaeleha, ho tima, ho halefisa, ho nyenyefatsa, ho etsa Carburization | |

| Shell Mold Casting | 0.66 lbs ho isa ho 440 lbs | CT8~CT12 | ||||

| Lahlehile Wax Investment Casting | Ho Lahlela Khalase ea Metsi | 3000 | Ts'epe e sa beng le mabali,Tšepe ea Carbon, Lisebelisoa tsa tšepe, Brass, Cast Aluminium, Duplex Stainless Steel | Ho tloha ho 0,1 ho isa ho 50 kg | CT5~CT9 | |

| 0.22 lbs ho isa ho 110 lbs | ||||||

| Silica Sol Casting | 1000 | 0.05 lik'hilograma ho 50 lik'hilograma | CT4~CT6 | |||

| 0.11 lbs ho isa ho 110 lbs | ||||||

| Ho Lahla Foam e Lahlehileng | 4000 | Tšepe e Bohlooho, Tšepe ea Ductile, Li-alloys tsa tšepe, Tšepe ea Carbon, Tšepe e se nang Mokelikeli | Ho tloha ho 10 ho isa ho 300 kg | CT8~CT12 | ||

| 22 lbs ho isa ho 660 lbs | ||||||

| Vacuum Casting | 3000 | Tšepe e Bohlooho, Tšepe ea Ductile, Li-alloys tsa tšepe, Tšepe ea Carbon, Tšepe e se nang Mokelikeli | Ho tloha ho 10 ho isa ho 300 kg | CT8~CT12 | ||

| 22 lbs ho isa ho 660 lbs | ||||||

| High Pressure Die Casting | 500 | Lisebelisoa tsa Aluminium, Lisebelisoa tsa Zinc | Ho tloha ho 0,1 ho isa ho 50 kg | CT4~CT7 | ||

| 0.22 lbs ho isa ho 110 lbs | ||||||