Custom grey cast ironlikhetla tse entsoeng ka hloboka litšebeletso tsaphekolo ea mochesole kalafo ya bokahodimo.

Shell molding castingprocess e boetse e bitsoa pre-coated resin sand casting process, hot shell molding castings kapa core casting process. Ntho e ka sehloohong ea ho bōptjoa ke lehlabathe la phenolic resin le koahetsoeng esale pele, le theko e boima ho feta lehlabathe le letala le lehlabathe la resin la furan. Ho feta moo, lehlabathe lena le ke ke la sebelisoa hape.

Mokhoa oa ho lahla lehlabathe la Furan resin (mokhoa oa nobake) o sebelisa lehlabathe le koahetsoeng ka lehlabathe la furan ho etsa hlobo ea ho lahla. Ka mor'a ho kopanya lehlabathe la pele (kapa lehlabathe le tsosolositsoeng), metsi a furan resin le catalyst ea metsi ka mokhoa o ts'oanang, ebe o li tlatsa ka lebokoseng la mantlha (kapa lebokose la lehlabathe), ebe o le tiisa hore le thatafale ka har'a hlobo kapa hlobo ka lebokoseng la mantlha (kapa lehlabathe). box) ka mocheso oa kamore. Joale ho ile ha thehoa hlobo ea ho lahla kapa ho lahla, e bitsoang "self-harding batang-core box molding" (konokono), kapa mokhoa oa ho ithatafatsa (konokono).

Hobane hlobo e entsoe ka mocheso oa kamore 'me ha ho hlokahale hore e futhumale, ho lahla lehlabathe le ithatafatsang ho boetse ho bitsoa mokhoa oa ho lahla o sa bake. Mokhoa oa ho ithatafatsa o ka aroloa ka acid-catalyzed furan resin le phenolic resin sand self-harding method, urethane resin sand in self-harding method le phenolic monoester self-harding.

Joalo ka lehlabathe le ithatafatsang la lebokose le batang, lehlabathe la resin la furan ke lehlabathe la pele le sebelisoang haholo hona joale le sebelisoang haholo setsing sa Machaena. Palo ea resin e kentsoeng lehlabatheng le bōpiloeng hangata ke 0.7% ho isa ho 1.0%, 'me palo ea resin e kentsoeng lehlabatheng la mantlha hangata ke 0.9% ho isa ho 1.1%. Likahare tsa aldehyde ea mahala ho resin ea furan li ka tlase ho 0.3%, 'me lifeme tse ling li theohetse ka tlase ho 0.1%. Libakeng tse thehiloeng Chaena, lehlabathe le ithatafatsang la furan resin le fihlile boemong ba machaba ho sa tsotellehe ts'ebetso ea tlhahiso le boleng ba holim'a li-castings.

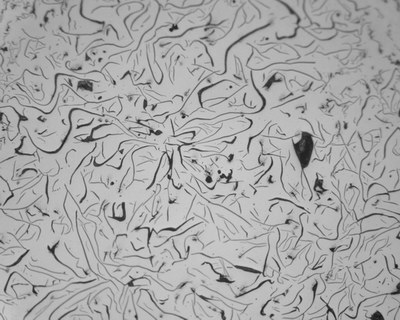

Grey iron, kapa grey cast iron, ke mofuta oa tšepe e entsoeng ka tšepe e nang le graphite microstructure. E bitsoa ka 'mala o moputsoa oa fracture eo e e etsang. The grey cast iron e sebelisoa bakeng sa matlo moo ho satalla ha motsoako ho leng bohlokoa ho feta matla a eona a thata, joalo ka li-cylinder tsa enjene e tukang ka hare, matlo a pompo, 'mele ea li-valve, mabokose a motlakase, boima ba li-counter le li-castings tse khabisitsoeng. Thermal conductivity ea Grey cast iron le matla a khethehileng a hlooho hangata a sebelisoa hampe ho etsa li-cookware tsa tšepe tse entsoeng ka tšepe le li-rotor tsa disc.

Sebopeho se tloaelehileng sa lik'hemik'hale ho fumana microstructure ea graphite ke 2.5 ho 4.0% carbon le 1 ho 3% silicon ka boima ba 'mele. Graphite e ka nka 6 ho isa ho 10% ea molumo oa tšepe e bohlooho. Silicon ke ea bohlokoa ho etsa tšepe e bohlooho ho fapana le tšepe e tšoeu ea tšepe, hobane silicon ke karolo ea graphite e tsitsitseng ka tšepe e entsoeng ka tšepe, e bolelang hore e thusa motsoako ho hlahisa graphite ho e-na le li-carbides tsa tšepe; ka 3% silicon hoo e ka bang ha ho na carbon e tšoaroang ka lik'hemik'hale hammoho le tšepe.

graphite e nka sebōpeho sa letlapa la mahlakore a mararo. Ka litekanyo tse peli, ha sebaka se bentšitsoeng se tla hlaha ka tlas'a microscope, li-flakes tsa graphite li hlaha e le mela e metle. Malebela a li-flakes a sebetsa joalo ka li-notch tse seng li le teng; ka hona, e brittle. Ho ba teng ha graphite flakes ho etsa hore Grey Iron e khonehe habonolo kaha e atisa ho petsoha habonolo ho pholletsa le li-graphite flakes. Grey iron e boetse e na le matla a matle haholo a ho phopholetsa, ka hona e sebelisoa haholo joalo ka motheo oa lisebelisoa tsa mochini.

Mechanical Properties of Grey Cast Iron | |||||||

| Ntho ho latela DIN EN 1561 | Lekanya | Yuniti | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Matla a tšepe | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Matla a Puno | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Elongation Matla | A | % | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 |

| Matla a Khatellang | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Matla a Khatellang | σd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Flexural Matla | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Ho Shear Khatello | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Li-module tsa elasticity | E | GPA | 78-103 | 88-113 | 103 - 118 | 108 - 137 | 123 - 143 |

| Nomoro ea Poisson | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Ho thatafala ha Brinell | HB | 160-190 | 180 - 220 | 190-230 | 200 - 240 | 210 - 250 | |

| Ductility | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Ho fetoha ha tsitsipano le khatello | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Matla a Qhoba | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Botenya | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Kereiti e lekanang ea Grey Cast Iron | ||||||||

| AISI | W-stoff | DIN | BS | SS | HLOMPHO | UNE / IHA | JIS | UNI |

| A48-20B | 0.6010 | GG-10 | Sehlopha sa 100 | 0110-00 | - | - | FC 100 | G 10 |

| A48-25B | 0.6015 | GG-15 | Sehlopha sa 150 | 0115-00 | Feta 15 D | FG 15 | FC 150 | G 15 |

| A48-30B | 0.6020 | GG-20 | Sehlopha sa 200 | 0120-00 | Fet 20 D | FG 20 | FC 200 | G 20 |

| A48-40B | 0.6025 | GG-25 | Sehlopha sa 250 | 0125-00 | Fet 25 D | FG 25 | FC 250 | G 25 |

| A48-45B | 0.6030 | GG-30 | Sehlopha sa 300 | 0130-00 | Ft 30 D | FG 30 | FC 300 | G 30 |

| A48-50B | 0.6035 | GG-35 | Sehlopha sa 350 | 0135-00 | Feta 35 D | FG 35 | FC 350 | G 35 |

| A48-60B | 0.6040 | GG-40 | Sehlopha sa 400 | 0140-00 | Feta 40 D | - | FC 40 | - |

| 32510 | GTS-35 | B340/12 | 0815-00 | MN 35-10 | - | FCMW 330 | - | |

| A220-40010 | 0.8145 | GTS-45 | P440/7 | 0852-00 | MN 450 | - | FCMP 440/490 | GMN 45 |

| A220-50005 | 0.8155 | GTS-55-04 | P510/4 | 0854-00 | MP 50-5 | - | FCMP 490 | GMN 55 |

| A220-70003 | 0.8165 | GTS-65-02 | P570/3 | 0856-00 | MN 650-3 | - | FCMP 590 | GMN65 |

| A220-70003 | - | GTS-65 | P570/3 | 0858 | MN 60-3 | - | FCMP 540 | - |

| A220-80002 | 0.8170 | GTS-70-02 | P690/2 | 0862-00 | MN 700-2 | - | FCMP 690 | GMN70 |

Resin Coated Lehlabathe Lahlela Metal le Alloys | |

| Metal & Alloys | Sehlopha se Tsebahalang |

| Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Tšepe ea ho Rala ea Ductile (Nodular). | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Tšepe ea Carbon | C20, C25, C30, C45 |

| Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Ts'epe e sa beng le mabali | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Pula e thatafatsa Stainless Steel, Duplex Stainless Steel |

| Lisebelisoa tsa Aluminium | ASTM A356, ASTM A413, ASTM A360 |

| Lisebelisoa tsa koporo / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, le GB | |

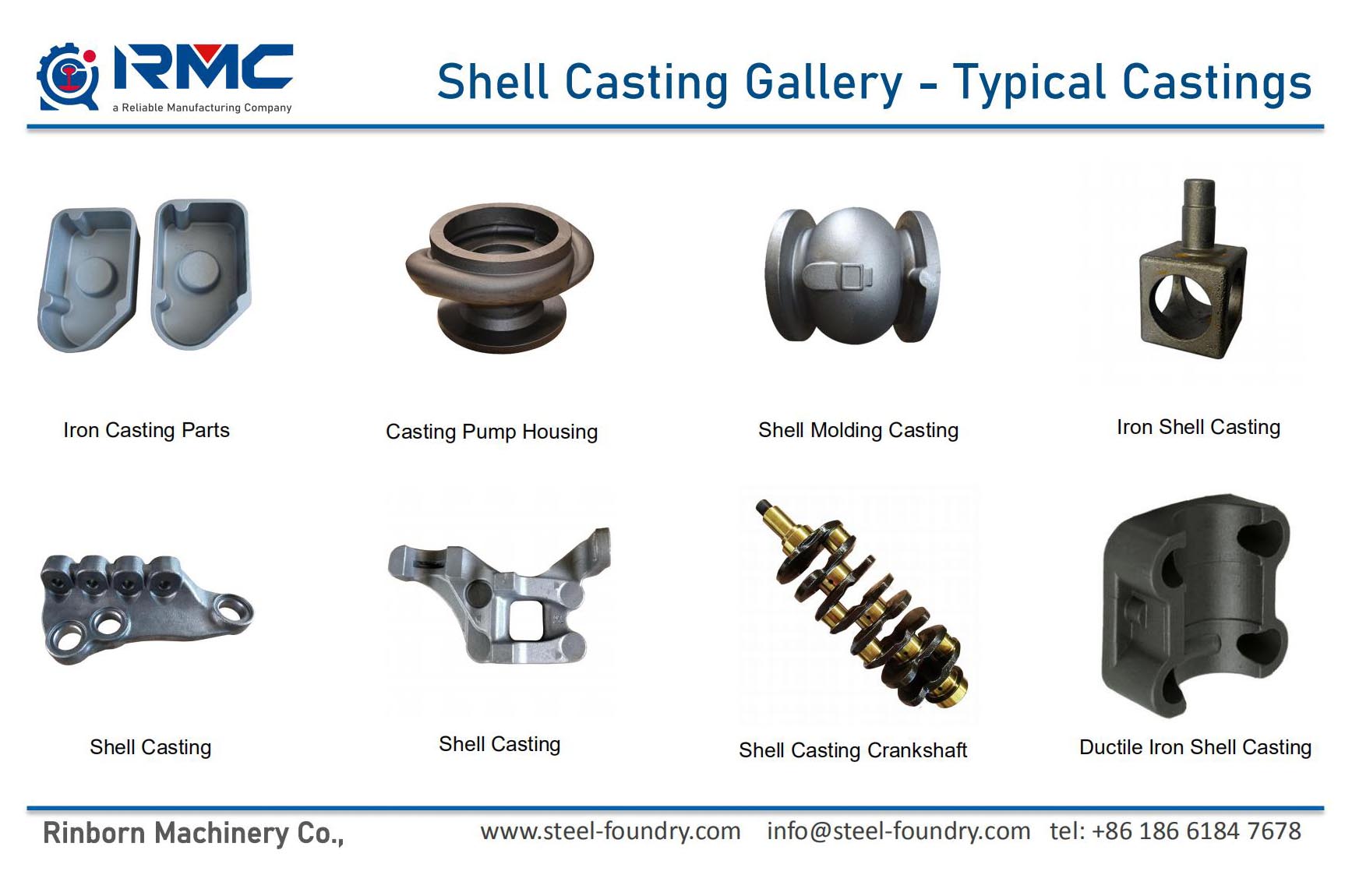

Lihlahisoa tse Tloaelehileng tsa ho Lahlela tšepe