Investment Casting Foundry

Ho lahla matsete, ho tsejoang hape e le ho lahleheloa ke boka ba boka kapa ho lahla ka mokhoa o nepahetseng, ke ts'ebetso e 'nileng ea etsoa ka lilemo tse likete,' me mokhoa o lahlehileng oa boka ke o mong oa mekhoa ea khale ka ho fetisisa e tsejoang ea ho etsa tšepe.

Ka lebaka la sebopeho se rarahaneng ka boholo le geometri, li-castings tsa matsete li hlahisoa ho fihlela sebopeho sa marang-rang kapa haufi le sebopeho sa marang-rang, ho fokotsa tlhokahalo ea lits'ebetso tsa bobeli tse kang lathing, turning kapa tse ling.Mechine ea CNCtshebetso.

Ho etsa matsete ke ts'ebetso ea tlhahiso e ka salang morao lilemong tse 5,000 tse fetileng. Ho tloha ka nako eo, ha boka ba boka ba linotsi bo theha mohlala, ho fihlela mehleng ea kajeno ea theknoloji e phahameng, lisebelisoa tsa refractory le li-alloys tse khethehileng, ho lahleheloa ke boka ba linotsi ho netefatsa hore likarolo tsa boleng bo phahameng li hlahisoa ka melemo ea ho nepahala, ho pheta-pheta le botšepehi.

Ts'ebetso ea matsete e fumana lebitso la eona molemong oa hore mohlala o tsetelitsoe, kapa o pota-potiloe, ka thepa e hanyetsang. Mekhoa ea boka e hloka tlhokomelo e feteletseng hobane ha e na matla a lekaneng ho mamella matla a kopaneng nakong ea ho etsa hlobo.

Investment Casting Foundry

Seo re ka se Finyellang ka ho Lahla Wax Investment Casting

Li-castings tse lahlehileng tsa boka ba lichelete tse nang le silica sol e le lintho tse tlamang li ka fihla sehlopheng sa mamello ea dimensional CT4 ~ CT7 ho latela ISO 8062. Lisebelisoa tsa rona tse hlophisitsoeng ka botlalo le li-automation process control controls li lumella ho mamellana ho tsitsitseng le ho pheta-pheta haufi le ± 0.1 mm. Thelikarolo tse lahliloeng tsa bokale tsona di ka hlahiswa ka mefuta e mengata ya boholo, di ka ba tse nyane ho fihla ho 10 mm ka bolelele x 10 mm bophara x 10 mm bophahamo mme boima bo ka bang 0.01 kg, kapa boholo bo ka fihlang ho 1000 mm ka bolelele le boima ba dikilogeramo tse 200. .

RMC ke moetsi ea etelletseng pele indastering ea matsete a boleng bo holimo a ikemiselitseng ho fana ka boleng bo holimo, boleng bo holimo le boiphihlelo bo ikhethang ba bareki. RMC e na le boiphihlelo, boitseanape ba botekgeniki le lits'ebetso tsa netefatso ea boleng ho fana ka mefuta e mengata e pharalletseng ea li-casts ka ts'ebetso e tsoelang pele.

- • Boholo ba ho Lahlela: 1,000 mm × 800 mm × 800 mm

- • Cast Weight RangeBoima: 0.5 lik'hilograma - 200 lik'hilograma

- • Bokhoni ba Selemo:3,000 lithane

- • Thepa ea Bond bakeng sa Kaho ea Shell:Silica Sol, Khalase ea Metsi kapa metsoako ea bona.

- • Mamello ea ho Lahla:CT4 ~ CT7 ho latela ISO 8062 kapa ka kopo.

Ho Etsa Likhetla Nakong ea Ho Etsa Matsete

Seo Litšepe le Alloys re ka li tšela ka Investment Casting

Thesetsi sa ho etsa licheleteho RMC e khona ho kopana le mefuta e mengata e fapaneng ea litlhaloso le litlhaloso ho latela maemo a ASTM, SAE, AISI, ACI, DIN, GOST, EN, ISO, le GB. Re na le li-alloys tse fetang 100 tse fapaneng tsa ferrous le tse se nang ferrous tseo ka tsona re akhelang likarolo ka mokhoa o rarahaneng oa moralo.

- • Grey Cast iron:HT150, HT200, HT250, HT300, HT350; EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300, EN-GJL-350; GG10, GG15, GG20, GG25, GG30, GG40; ASTM A48 Gray Iron Grades Class 20, Class 25, Class 30, Class 35, Class 40, Class 45, Class 50, Class 55, Class 60.

- • Tšepe ea Ductile Cast (Nodular Aron):China GB QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2; GGG40, GGG45, GGG50, GGG60, GGG70, GGG80; EN-GJS-400-18, EN-GJS-400-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2, EN- GJS-800-2; ASTM A536 Ductile Iron Kereiti 60-40-18, 65-45-12, 70-50-05, 80-60-03, 100-70-03, 120-90-02.

- •Tšepe ea Carbon:AISI 1020 ~ AISI 1060, C30, C40, C45.

- •Alloy Steel:ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo, joalo-joalo.

- •Ts'epe e sa beng le mabali:AISI 304, AISI 304L, AISI 316, AISI 316L,AISI 347, AISI 430, 1.4401, 1.4404, 1.4408, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571, CF3, CF3M, CF8, CF8M ... joalo-joalo.

- •Duplex Stainless Steel (DSS)lePula e thatafatsang (PH) Tshipi e sa Kgethehang

- • Brass, Bronze le Lisebelisoa tse ling tsa Copper-based

- •Nickel Based Alloy (Inconel 625, Inconel 713, Inconel 718 joalo-joalo), Cobalt Based Alloys

- • Tšepe e hananang le ho bola, Tšepe e hananang le metsi a Leoatleng, Tšepe ea Mocheso o Holimo, Tšepe e Tletseng matla, Tšepe ea Duplex Stainless.

- • Aluminium Alloy A356, A360

- • Lisebelisoa tse ling e le kopo kapa ho latela ASTM, SAE, AISI, GOST, DIN, EN, ISO, le GB.

Stainless Steel Investment Casting

Investment Casting Mold

Al Mold bakeng sa ho Lahla boka ba Lahlehileng

Metal Mold bakeng sa ho Lahlela Matsete

Aluminium Alloy Mold e entsoeng ka ho Fetisisa bakeng sa Precision Casting

Mehato ea Last Wax Investment Casting

Ts'ebetso ea lichelete ke ts'ebetso ea mehato e mengata e hlahisang sebopeho se haufi-ufilikarolo tse nepahetseng tsa ho lahla. Ts'ebetso e qala ka boka ba boka bo kenngoa ka har'a sefu ho etsa mohlala oa sehlahisoa se felileng. Joale lipaterone li khomareloa ho li-runner bars ho etsa sehlopha.

Nakong ea ts'ebetso ea ho kenya lichelete, mochine o khethehileng o qoelisa sehlopha ka makhetlo a mangata ka har'a slurry ho hlahisa khetla ea ceramic, ebe boka ba boka bo tlosoa ka har'a autoclave ea mouoane. Hang ha boka ba boka bo tlosoa, khetla ea ceramic e chesoa ebe e tlatsoa ka tšepe e qhibilihisitsoeng ho etsa karolo. Molemo o mong oa ho etsa matsete ke hore boka bo ka sebelisoa hape.

Ho lahla matsete (Lost wax casting process) ho hloka hore tšepe e shoe (hangata ka aluminium), boka, seretse se entsoeng ka ceramic, sebōpi, tšepe e qhibilihisitsoeng, le mechine e meng e hlokahalang bakeng sa ente ea boka, ho phatloha ha lehlabathe, ho thothomela, ho rema le ho sila. Ts'ebetso ea ho etsa matsete haholo e kenyelletsa mehato e latelang:

1- Ho Etsa Metal Die

Ho ipapisitsoe le lits'oants'o le litlhoko tsa karolo e lahliloeng, tšepe e shoang kapa hlobo, hangata e le aluminium, e tla raloa le ho hlahisoa. Sekoti se tla etsa boholo bo lekanang le sebopeho sa karolo e lahliloeng e lahliloeng.

2- Ente ea boka

E boetse e tsejoa e le sebopeho sa paterone, Lipaterone tse lahlehileng tsa boka li entsoe ka ho kenya boka bo qhibilihisitsoeng ka har'a tšepe e ka holimo.

3- Seboka sa Slurry

Joale lipaterone tsa boka li hokelloa ka har'a lekhalo, leo hangata e leng sete ea likanale tseo tšepe e qhibilihisitsoeng e phallelang lesobeng la hlobo. Ka mor'a moo, mohaho o kang sefate o thehoa, o loketseng tlhahiso ea bongata.

4- Mohaho oa Shell

The investment castings outer shell casing e hahiloe ka ho qoelisoa ka bateng ea ceramic ebe hang-hang e koaheloa ka lehlabathe ka makhetlo a 'maloa.

5- Ho tlosa boka

Karolo e ka hare ea matsete a nepahetseng e ntan'o tlosoa dewax, e sieang lesela le ka ntle la khetla ea ceramic e se nang letho. Likoti ke sebaka se ts'oanang le sa li-castings tse lakatsehang.

6-Tlhahlobo ea Pele ho Tšela

Tlhahlobo ea pele ho tšolloa e bolela hore setsi sa motheo se hloka ho hlahloba le ho hlahloba metsoako ea lik'hemik'hale ea tšepe e qhibilihisitsoeng ho bona hore na e kopana le linomoro tse hlokahalang kapa stardard. Ka linako tse ling, tlhahlobo ena e ne e tla etsoa ka makhetlo a 'maloa.

7- Ho tshela & Ho tiisa

Khetla ea ceramic e nang le cavity e lokela ho futhumatsoa pele e tšela. Sena se thibela ho tsosoa le khetla ea ceramic hore e se ke ea phunyeha hang ha tšepe ea metsi ka mocheso o phahameng e tšeloa ka har'a sekoti.

8- Ho sakha kapa ho poma

Hang ha tšepe e se e pholile 'me e tiile, karolo (li)karolo e tlosoa ho tloha sehlopheng sa sefate sa gating system ka ho sisinyeha, ho itšeha kapa ho ferekanngoa ho tloha karolong ea motho ka mong.

9- Shot Blasting le Secondary Processing

Karolo ea ho lahla e ka etsoa ka ho feletseng ka ho sila kapa ho phekola mocheso o eketsehileng. Ho ka 'na ha hlokahala hore mochini oa bobeli kapa kalafo ea holim'a metsi le eona e hlokehe ho latela litlhoko tsa karolo.

10-Ho paka le ho Romela

Ebe likarolo tse lahliloeng tsa boka li tla lekoa ka botlalo bakeng sa litekanyo, bokaholimo, thepa ea mochini le liteko tse ling tse hlokahalang pele li paka le ho pepa.

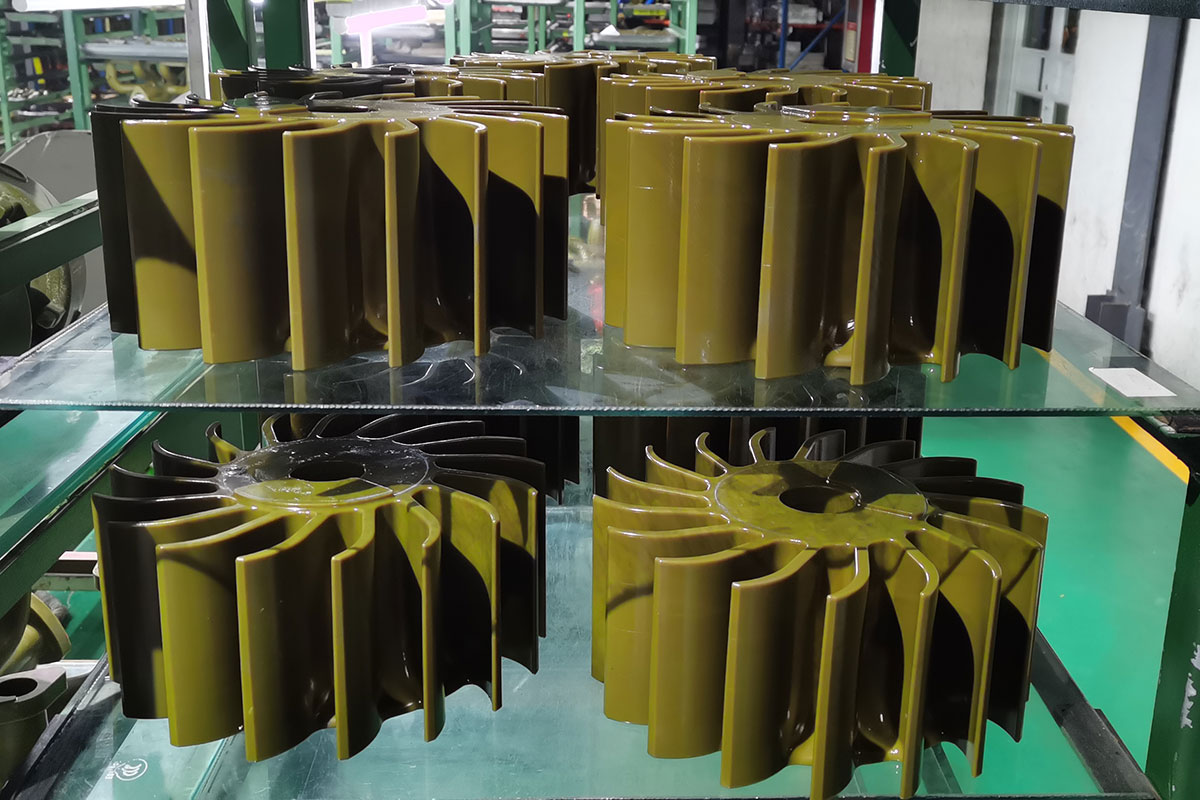

Mehlala ea boka

Ho Omisa Likhetla

Ho pholisa le ho Tiisa

Ho sila le ho Hloekisa

Kamoo re Hlahlobang Lits'ebetso tsa Matsete

- • Spectrographic and manual quantitative analysis

- • Tlhahlobo ea metallographic

- • Liteko tsa boholo

- • CMM

- • Tlhahlobo ea thata ea Brinell, Rockwell le Vickers

- • Tlhahlobo ea thepa ea mechine

- • Teko ea tšusumetso e tlase le e tloaelehileng ea mocheso

- • Tlhahlobo ea bohloeki

- • tlhahlobo ea UT, MT le RT

- • Staic and Dynamic Balancing

- • Teko ya Ho Tiisa le Kgatello

Wax Replicas

Ke Lisebelisoa life tseo re itšetlehileng ka tsona bakeng sa Investment Casting

Toolings Warehouse

Ente ea Wax Patterns

Ente ea Wax Patterns

Mochini oa Kente ea boka

Ho Etsa Likhetla

Ho Etsa Likhetla

Seboka sa ho omisa likhetla

Shell bakeng sa Investment Casting

Ho Omisa Likhetla

Shell e Itokiselitse ho Latsoa

Ho pholisa le ho Tiisa

Ts'ebetso ea ho Lahlela Matsete

Ke Liindasteri life tseo Lichelete tsa rona tsa Matsete li li sebeletsang

Likarolo tse entsoeng ka ho kenya cheleteli sebelisetsoa ho lahlela lintho tse ngata tse fapaneng, ho kenyeletsoa boleng bo holimo, likarolo tsa indasteri tse sebetsang hantle tsa meaho e rarahaneng.Ts'ebeliso ea likarolo tsa ho etsa matsete e akaretsa mefuta e fapaneng ea liindasteri, k'hamphaning ea rona hangata li sebelisoa libakeng tse latelang:

| •Likarolo tsa Valove le Pompo | • Thepa ea thepa |

| • Lilori tse Boima | • Thepa ea Temo |

| • Tsa makoloi | •Li-hydraulics |

| • Thepa ea Kaho | • Literene tsa Terene |

Likopo tsa Investment Castings

E tloaelehilengInvestment CastingsRe Hlahisa

Re ka Etsa ho eketsehileng ka ho fana ka Investment Casting le Litšebeletso tse ling:

Ho RMC, re motlotlo ka ho fa bareki ba rona ts'ebeletso ho tloha ho moralo oa patter ho eali-castings tse felilengle mekhoa ea bobeli. Litšebeletso tsa rona li kenyelletsa:

- - Litlhahiso tsa Moralo oa Paterone le Litlhahiso tsa Theko e tlase.

- - Ntlafatso ea Prototype.

- - Lipatlisiso tsa Tlhahiso le Ntlafatso.

- - Ho Fetolana ha Tlhahiso.

- - Litšoaneleho le Teko.

- - Kalafo ea Mocheso le Phekolo ea Bokaholimo lia fumaneha.

- - Outsourcing Manufacturing Uwezo

Lits'enyehelo tsa tšepe tse se nang tšepe

Hobaneng U Khetha RMC bakeng sa ho Hlahisa Investment Castings

Ho na le mabaka a 'maloa a ho khetha RMC e le mohloli oa hau oa ho etsa matsete. Ha u etsa qeto, u ka tsotella lintlha tse latelang tseo re leng molemo ho li sebeletsa:

- - Sehlopha sa boenjiniere bao litho tsa bona li tsepamisitseng maikutlo lebaleng la ho akhela tšepe.

- - Boiphihlelo bo pharalletseng ka likarolo tse rarahaneng tsa li-geometri

- - Mefuta e mengata e fapaneng ea lisebelisoa, ho kenyeletsoa li-alloys tse nang le ferrous le non-ferrous

- - Ka tlungMechine ea CNCbokgoni

- - Tharollo e le 'ngoe ea ho etsa matsete le ts'ebetso ea bobeli

- - Boleng bo tsitsitseng bo tiisitsoe le ntlafatso e tsoelang pele.

- - Tšebelisano 'moho ho kenyeletsoa baetsi ba lisebelisoa, baenjiniere, setsebi, setsebi sa machini le litsebi tsa tlhahiso.