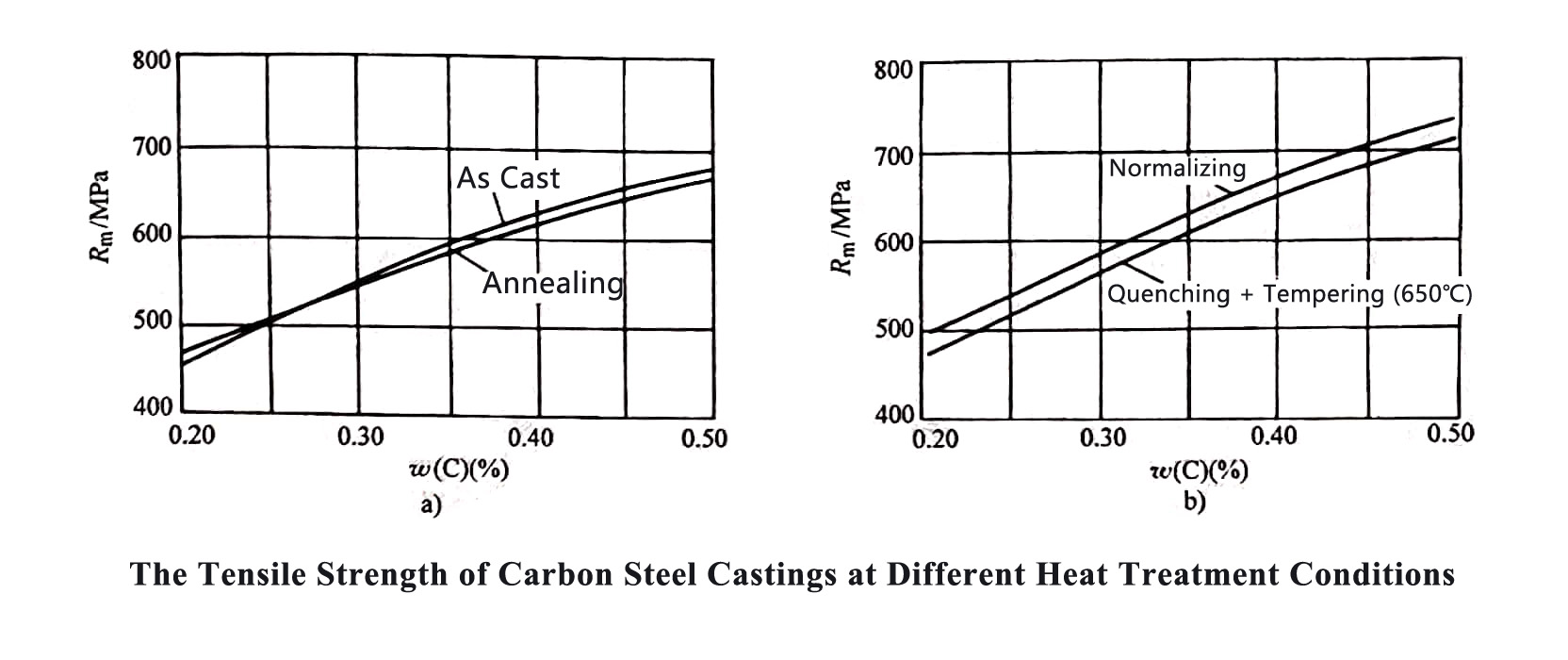

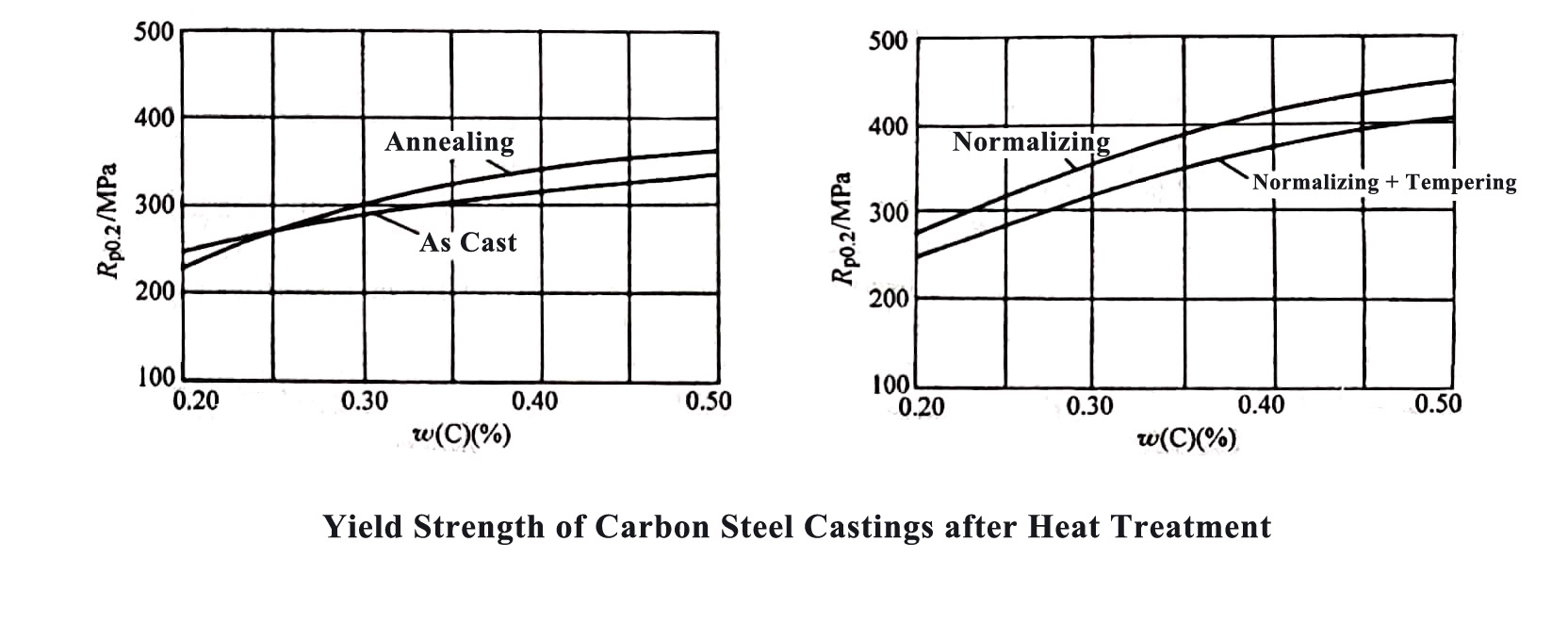

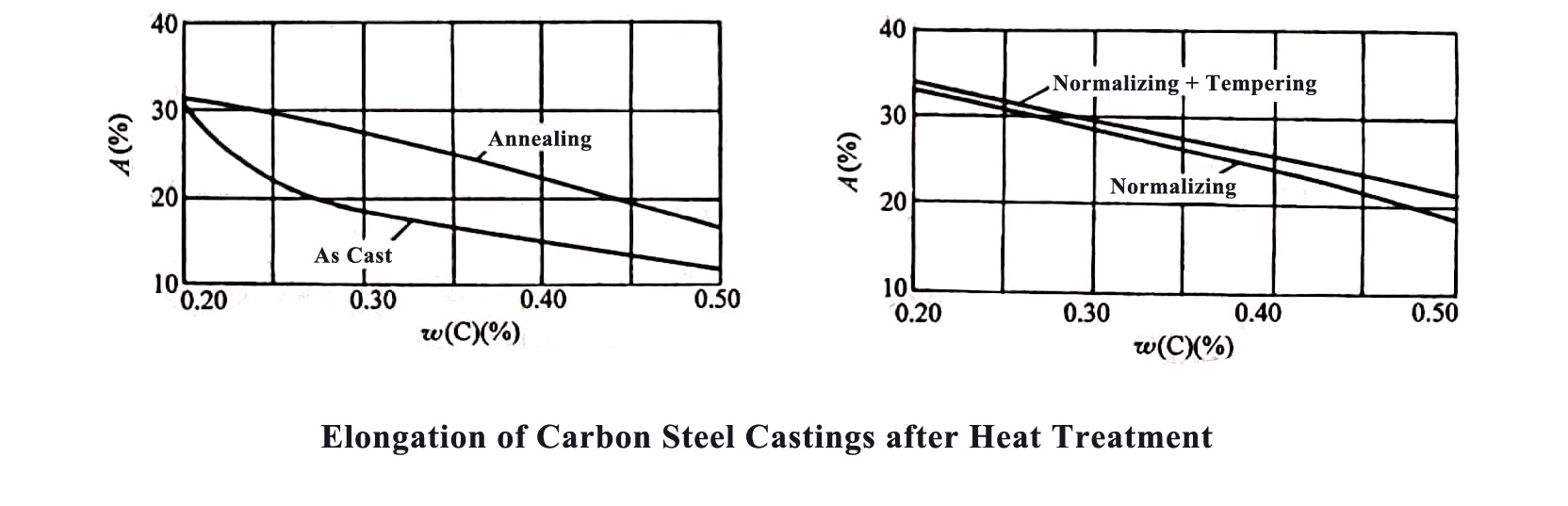

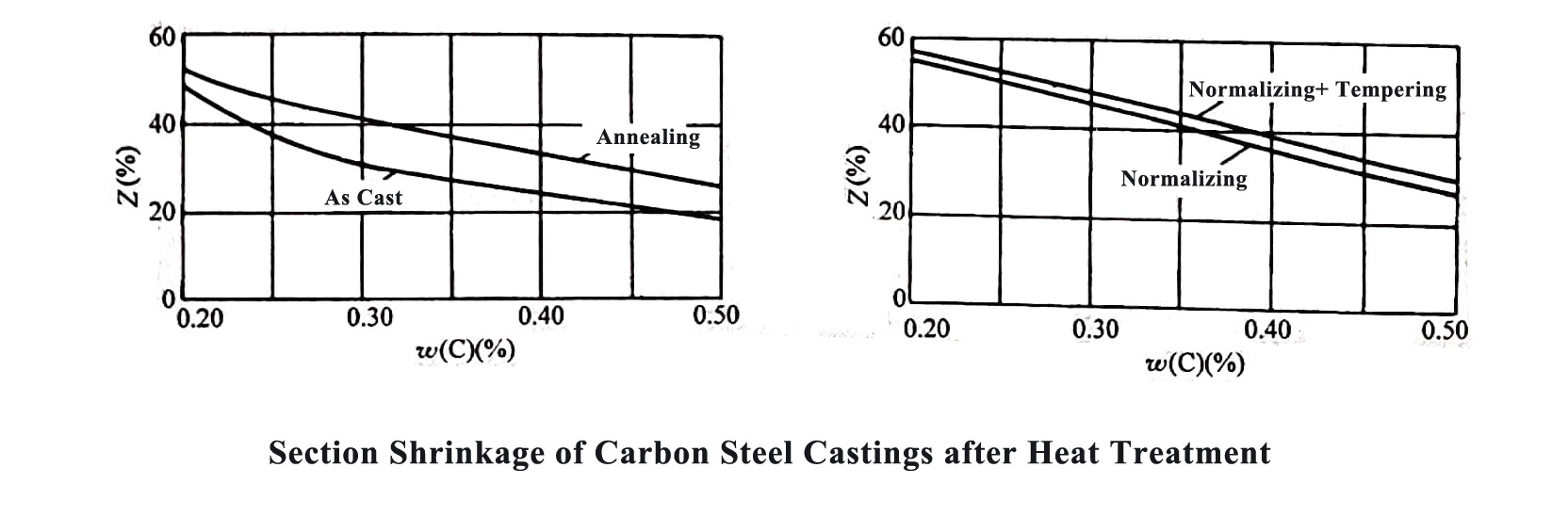

Mekhoa ea phekolo ea mocheso e atisang ho sebelisoa bakeng sa li-castings tsa carbon steel ke: annealing, normalizing kapa normalizing + tempering. Tšusumetso ea mekhoa ena e meraro ea phekolo ea mocheso holim'a thepa ea mechine ea tšepe e entsoeng ka carbon e bontšoa setšoantšong se ka tlase.

| Thempereichara e Anelang le ho Thata ha Litšepe tsa Carbon | ||||||

| Kereiti ea Carbon Steel | Khabone / % | Anealing Mocheso / ℃ | Ho Tšoara Nako | Mokhoa oa ho Pholisa | Ho thatafala / HBW | |

| Botenya ba Lerako / mm | Nako / h | |||||

| ZG200 - 400 | 0.10 - 0.20 | 910 - 880 | < 30 | 1 | Ho bata ho fihla ho 620 ℃ ka har'a libopi ebe ho pholile moeeng | 115 - 143 |

| ZG230 - 450 | 0.20 - 0.30 | 900 - 870 | 133 - 156 | |||

| ZG270 - 500 | 0.30 - 0,40 | 890 - 860 | 143 - 187 | |||

| ZG310 - 570 | 0.40 - 0,50 | 870 - 840 | 30 - 100 | eketsa 1 hora / 30 mm | 156 - 127 | |

| ZG340 - 640 | 0,50 - 0,60 | 860 - 830 | 187-230 | |||

Thepa ea mochini ea tšepe ea tšepe e tloaelehileng e phahame hanyane ho feta ea tšepe ea annealed cast. Kaha tekanyo ea undercooling nakong ea phetoho ea sebopeho e batla e le khōlō, boima bo tla ba bo phahameng, 'me ts'ebetso ea eona ea ho itšeha le eona e molemo.

| Ho tloaeleha le ho thatafala ha Carbon Steel Castings | |||||

| Kereiti ea Carbon Steel | Khabone (%) | Normalizing Mocheso / ℃ | Ho halefisa | Ho thatafala / HBW | |

| Mocheso / ℃ | Mokhoa oa ho Pholisa | ||||

| ZG200 - 400 | 0.10 - 0.20 | 930 - 890 | 540 - 610 | seboping kapa moyeng | 126 - 149 |

| ZG230 - 450 | 0.20 - 0.30 | 930 - 890 | 540 - 610 | seboping kapa moyeng | 139 - 169 |

| ZG270 - 500 | 0.30 - 0,40 | 890 - 860 | 550 - 620 | seboping kapa moyeng | 149 - 187 |

| ZG310 - 570 | 0.40 - 0,50 | 890 - 850 | 550 - 650 | seboping kapa moyeng | 163 - 217 |

| ZG340 - 640 | 0,50 - 0,60 | 870 - 830 | 550 - 650 | seboping kapa moyeng | 187-228 |

Bakeng sa li-castings tsa carbon steel tse nang le lik'habone tse phahameng le libopeho tse rarahaneng, e le ho felisa khatello ea kelello e setseng le ho ntlafatsa ho thatafala, phekolo ea tempering e ka etsoa ka mor'a hore e tloaelehe. Thempereichara ea mocheso hangata ke 550 ℃-650 ℃, ebe e pholile moeeng.

Ha carbon content e phahame ho feta 0.35%, likarolo tsa carbon steel li ka tima le ho halefa (ho tima + mocheso o phahameng oa mocheso). Lisebelisoa tse nyane tsa tšepe tsa carbon li ka tingoa ka kotloloho le ho halefa maemong a joalo-joalo; li-castings tse kholo kapa tse rarahaneng tse nang le sebōpeho sa carbon li lokela ho tima le ho halefa ka mor'a hore li tloaelehe.

| Thempereichara ea ho tima le ho futhumatsa le ho thatafala ha litšepe tsa carbon | |||

| Khabone % | Quenching Mocheso / ℃ | Temperature Mocheso / ℃ | Thata ka mor'a ho halefa / HBW |

| 0.35 - 0.45 (Sehlopha se Senyenyane) | 850 - 830 (Ho Pholisa ka Metsing) | 300-400 | 364 - 444 |

| 400 - 450 | 321 - 415 | ||

| 510 - 550 | 241 - 286 | ||

| 540 - 580 | 228 - 269 | ||

| 580 - 640 | 192-228 | ||

| 0.45 - 0.55 (Sehlopha se Senyenyane) | 830 - 810 (Ho Pholisa ka Metsing Kapa Oli) | 550 - 630 | 220 - 240 |

| 450 | ≈ 269 | ||

| 550 | ≈ 248 | ||

| 650 | ≈ 228 | ||

| 0.30 - 0.40 (Sehlopha sa Boima) | 840 -880 (Ho Pholisa ka Metsing Kapa Oli) | 520 - 550 | 229 - 269 |

| 530 - 560 | 217 - 255 | ||

| 540 - 570 | 207-241 | ||

| 550 - 580 | 187-229 | ||

| 0.40 - 0.50 (Sehlopha sa Boima) | 820 - 840 (Ho Pholisa ka Metsing Kapa Oli) | 530 - 560 | 229 - 269 |

| 550 - 580 | 217 - 255 | ||

| 560 - 590 | 207-241 | ||

| 570 - 600 | 187-229 | ||

Nako ea poso: Jul-23-2021