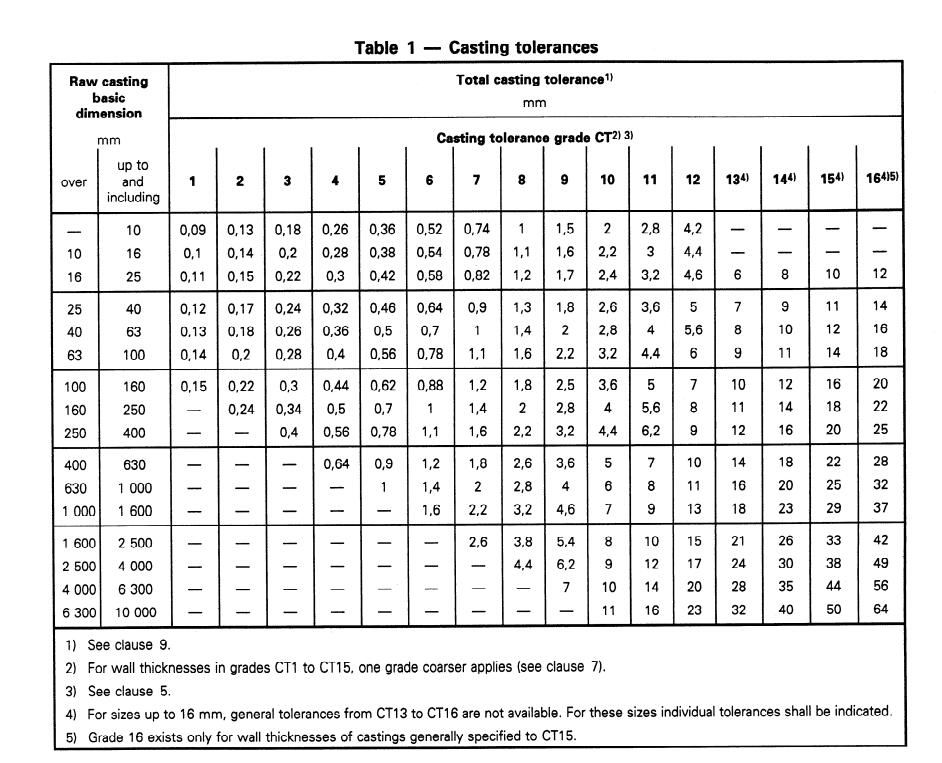

Mamello ea boholo ke ntlha ea bohlokoa ha re khetha mokhoa oa ho lahla bakeng sa li-castings tse lakatsehang. Ho ISO 8062 (e tsamaellanang le China's GB/T6414-1999) litokomane tse tloaelehileng, maemo a mamello a litekanyo tsa ho lahlela a hlalositsoe ka ho hlaka. Ka kakaretso, ts'ebetso ea matsete a matsete le ea ho etsa matsete e na le ho nepahala ho hoholo mme ke ka lebaka leo ts'ebetso ea ho etsa matsete e boetse e bitsoa.ho etsa ka nepo. Mona ho tse latelang u tla bona mamello e akaretsang ea li-castings ka mekhoa e fapaneng ea ho lahla.

Mamello ea ho Lahla le Bokhoni ho RMC Foundry | ||||||

| Mokhoa oa ho Lahlela | Bokhoni ba Selemo / Lithane | Lisebelisoa tse ka Sehloohong | Boima ba ho lahla | Kereiti ea Mamello ea ho Lahla ea Dimensional (ISO 8062) | Kalafo ea Mocheso | |

| Ho Lahlela Lehlabathe le Letala | 6000 | Grey Cast Iron, Ductile Cast Iron, Cast Al, Brass, Cast Steel, Stainless Steel | 0.3 lik'hilograma ho 200 lik'hilograma | CT11~CT14 | Ho tloaeleha, ho tima, ho halefisa, ho nyenyefatsa, ho etsa Carburization | |

| Resin Coated Sand Casting (Shell Casting) | 0.66 lbs ho isa ho 440 lbs | CT8~CT12 | ||||

| Lahlehile Wax Investment Casting | Ho Lahlela Khalase ea Metsi | 3000 | Ts'epe e sa beng le mabali, Carbon Steel, Alloy Steel, Brass, Aluminium, Duplex Stainless Steel, Cast Iron | Ho tloha ho 0,1 ho isa ho 50 kg | CT5~CT9 | |

| 0.22 lbs ho isa ho 110 lbs | ||||||

| Silica Sol Casting | 1000 | 0.05 lik'hilograma ho 50 lik'hilograma | CT4~CT6 | |||

| 0.11 lbs ho isa ho 110 lbs | ||||||

| Ho Lahla Foam e Lahlehileng | 4000 | Grey Aron, Ductile Iron, Alloy, Carbon Steel, Stainless Steel, Brass, Al | Ho tloha ho 10 ho isa ho 300 kg | CT8~CT12 | ||

| 22 lbs ho isa ho 660 lbs | ||||||

| Vacuum Casting | 3000 | Tšepe e Bohlooho, Tšepe ea Ductile, Alloy Steel, Carbon Steel, Stainless Steel | Ho tloha ho 10 ho isa ho 300 kg | CT8~CT12 | ||

| 22 lbs ho isa ho 660 lbs | ||||||

| High Pressure Die Casting | 500 | Lisebelisoa tsa Aluminium, Lisebelisoa tsa Zinc | Ho tloha ho 0,1 ho isa ho 50 kg | CT4~CT7 | ||

| 0.22 lbs ho isa ho 110 lbs | ||||||

Casting Tolerances bakeng saLehlabathe la Castings

Mamello ea ho lahla e arotsoe ka Dimensional Casting Tolerances (DCT) le Geometrical Casting Tolerances (GCT). Setsi sa rona se ka thabela ho bua le uena haeba u na le kopo e khethehileng mabapi le mamello e hlokahalang. Mona ho tse latelang ke boemo ba ho mamellana ka kakaretso boo re ka bo fihlelang ka ho lahla lehlabathe le letala, ho lahla hlobo ea likhetla le lehlabathe le sa bakeng la furan resin:

- ✔ DCT Kereiti ka Green Sand Casting: CTG10 ~ CTG13

- ✔ DCT Kereiti ka Shell Mold Casting kapa Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ Kereiti ea GCT ka Green Sand Casting: CTG6 ~ CTG8

- ✔ Kereiti ea GCT ka Shell Mold Casting kapa Furan Resin Sand Casting: CTG4 ~ CTG7

Casting Tolerances bakeng saInvestment Castings

Ho ea ka lisebelisoa tse fapaneng tsa ho kopanya tse sebelisetsoang ho etsa khetla, lichelete tsa lichelete li ka aroloa ka silika sol casting le khalase ea metsi. Ts'ebetso ea ho etsa matsete a silica sol e na le mamello e ntle ea Dimensional Casting Tolerances (DCT) le Geometrical Casting Tolerances (GCT) ho feta ts'ebetso ea khalase ea metsi. Leha ho le joalo, esita le ka mokhoa o ts'oanang oa ho lahla, Kereiti ea Mamello e tla fapana le alloy e 'ngoe le e' ngoe ka lebaka la bokhoni ba bona bo fapaneng. Setsi sa rona se ka thabela ho bua le uena haeba u na le kopo e khethehileng mabapi le mamello e hlokahalang. Mona ho tse latelang ke maemo a kakaretso a mamello ao re ka a fihlelang ka bobeli ka ho lahla silika le lits'ebetso tsa ho lahla likhalase tsa metsi ka thoko:

- ✔ DCT Kereiti ka Silica Sol Lost Wax Casting: DCTG4 ~ DCTG6

- ✔ DCT Kereiti ka Metsi Glass Lost Wax Casting: DCTG5 ~ DCTG9

- ✔ Kereiti ea GCT ka Silica Sol Lost Wax Casting: GCTG3 ~ GCTG5

- ✔ Kereiti ea GCT ka Glass ea Metsi e Lahlehileng Wax Casting: GCTG3 ~ GCTG5

Mamello ea ho Lahlela bakeng sa Shell Mold Castings

Joalo ka ha re boletse ka mamello ea ho lahla lehlabathe, likhetla tsa hlobo li na le ho nepahala ho phahameng haholo le mamello e matla ho feta ho lahla lehlabathe. Mona ho tse latelang ke boemo ba ho mamellana ka kakaretso boo re ka bo fihlelang ka ho lahla hlobo ea likhetla le ho lahla lehlabathe la furan resin:

- ✔ DCT Kereiti ka Shell Mold Casting kapa Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ Kereiti ea GCT ka Shell Mold Casting kapa Furan Resin Sand Casting: CTG4 ~ CTG7

Mamello ea ho Lahlela bakeng sa ho Lahleha ha Foam Castings

Ka kakaretso, mamello ea ho lahla foam e lahlehileng e molemo ho feta ho lahlela lehlabathe, empa e mpe ho feta ho lahla hlobo ea khetla le mekhoa ea ho lahlela e sa bake. Bakeng sa setsi sa rona, re ka fumana limaraka tse latelang tsa ho bapala. Empa re rata ho bua le uena ka libapali tse ikhethileng ebe re etsa qeto ea hore na re ka u fa linomoro life.

- ✔ Kereiti ea DCT ka ho Lahla Foam Casting: CTG9 ~ CTG13

- ✔ Kereiti ea GCT ka ho Lahla Foam Casting: CTG5 ~ CTG8

Haeba tokomane ea ho lahla kapa tokomane ea ts'ebetso e hloka tlhahlobo ea litekanyo tsohle tsa ho lahlela, litekanyo tsohle tsa ho lahlela li hloka ho hlahlojoa. Boemo bona hangata ke karolo ea pele ea tlhahiso ea li-castings kapa ts'ebetso ea tlhahlobo e sa reroang ea sampole nakong ea tlhahiso ea bongata. Ka tlhahiso ea li-batch tse nyane, ka linako tse ling ho hlokahala ho hlahloba litekanyo tsohle tsa ho lahla.

Ho ea ka litlhoko tse boletsoeng litšoantšong kapa litokomaneng tsa ts'ebetso, litekanyo tsa li-castings li hloka ho hlahlojoa bakeng sa litekanyo tsa bohlokoa tsa taolo, litekanyo tse nang le litlhoko tse phahameng tsa ho nepahala, le litekanyo tse holofetseng habonolo le tse sa mamelleheng. Boemo bona hangata bo sebelisoa tlhahlobong ea taolo ea litekanyo tsa tlhahiso ea bongata moleng oa tlhahiso.

Lihlahisoa tse Tloaelehileng tsa ho Lahlela tšepe

Lihlahisoa tsa ductile Iron Casting

Nako ea poso: Apr-14-2021