Cast iron, eo haholo-holo e koahelang bohlooho tšepe, ductile cast iron, cast mealleable iron le tse ling tse phahameng alloy cast iron, e sebelisoa haholoRMC Casting Foundry. Litšepe tse entsoeng ka tšepe li bapala karolo ea bohlokoa holiindasteri tsa kajeno. Ho khetha mekhoa e nepahetseng le e loketseng ea ho lahla e entsoeng ka tšepe e entsoeng ka tšepe e tla u thusa ho fumana li-castings tsa tšepe ka litšenyehelo tse tlaase le nako e khutšoanyane.

Mona ho tse latelang re sisinya melao-motheo kapa lintlha tse ling ha re khethamekhoa e loketseng ea ho lahlabakeng sa lisebelisoa tsa tšepe tse entsoeng ka tšepe. Ka kakaretso, mokhoa o sebelisoang ka ho fetisisa oa ho lahla tšepe ke ho lahla lehlabathe, ho lateloa ke mekhoa e khethehileng ea ho lahla, e kang ho lahla hlobo ea tšepe, ho kenya lichelete, ho lahla khetla,foam e lahlehilengle vacuum casting.

1- Ho Lahlela Lehlabathe E Lokela ho ba Khetho ea Pele

Haholo-holo ka lebaka la theko e tlaase le tlhahiso e bonolo eamokhoa oa ho lahla lehlabathe, ho lahla lehlabathe ho nkile hoo e ka bang 60% ho isa ho 70% ea kakaretso ea tlhahiso ea ho lahla, 'me hoo e ka bang 70% ea eona ke ho lahla lehlabathe le letala. Ha lehlabathe le letala le ke ke la finyella litlhoko mme joale o ka nahana ka tšebeliso ea lehlabathe le omileng kapa lehlabathe le leng. Boima ba ho lahla lehlabathe le letala ho tloha ho lik'hilograma tse 'maloa ho ea ho tse makholo a lik'hilograma, ha tlhahiso ea letsopa le omeletseng e ka ba boima ba lithane tse' maloa.

Mokhoa oa ho etsa lehlabathe o sebelisa mefuta ea lehlabathe ho etsa hlobo. E ka boela ea aroloa ka mefuta e meraro:

1) Ho Lahlela Lehlabathe le Letala, tse sebelisang lehlabathe le metsi (le tala) ho etsa hlobo.

2) Resin Coated Sanding Castingle No-bake Sand Mold Casting (Self-hardening Resin Sand Casting), e sebelisang lisebelisoa tse kopantsoeng ke lik'hemik'hale ho thusa ho theha mekhoa ea ho bōpa.

3) Lehlabathe le omeletseng, eo haholo-holo e sebelisang se omileng ntle le lik'hemik'hale tsa lik'hemik'hale bakeng sa ho bōpa. Mokhoa oa ho lahla lehlabathe le omileng haholo-holo o bua ka ho lahleheloa ke foam levacuum casting.

Ha re bua ka kakaretso, bakeng sa litšepe tse mahareng le tse kholo, ho lahla lehlabathe la lehlabathe le thata e ka ba khetho e ntle. Empa mabapi le tšepe ea motsoako le lisebelisoa tsa tšepe ea carbon, re ka khetha lehlabathe la khalase ea metsi. Sena se ka fumana litekanyo tse nepahetseng, bokaholimo bo boreleli ba li-castings, ha li na le litšenyehelo tse tlase ho feta ts'ebetso ea ho etsa matsete a silica sol.

Ho nepahala, ho qeta holimo, boima ba thepa le microstructure, thepa ea mechine e ka 'na ea se ke ea finyella litlhoko tse thata haeba u e-na le litebello tse khethehileng le tse phahameng. Tabeng ena, mekhoa e meng ea ho lahla e kang silica sol kapa metsi a matsete a khalase ea metsi, ho lahlela lefu, ho lahlela khatello e tlaase, ho lahleheloa ke foam le vacuum casting e lokela ho nkoa mahlong a rona.

2- Nahana ka Tlhokahalo ea Selemo le Selemo

Haeba tlhokahalo ea hau ea selemo le selemo e phahame, mohala oa ho bōpa o itekanetseng e lokela ho ba khetho e ntle ka ho fetisisa ka lebaka la matla a eona a maholo a tlhahiso le boleng bo tsitsitseng. 'Me mokhoa ona o ka finyella litšenyehelo tse tlaase tsa karolelano hafeela palo e hlokahalang e le khōlō ka ho lekaneng. Leha ho le joalo, ho bopa ka letsoho ho tla boloka litšenyehelo tsa hau haeba palo ea hau e se kholo hakaalo, kapa li-castings tseo u li batlang li le boholo bo mahareng kapa tse kholo.

Leha ho le joalo, mokhoa oa ho lahla lehlabathe la resin (shell moulding) o boetse o loketse litšepe tsa boholo bo boholo. Ho feta moo, ho lahla likhetla ho na le qetello e ntle le boleng bo phahameng ho feta mekhoa ea ho lahla lehlabathe le letala.

Lits'ebetso tse ling tse joalo ka khatello e tlase ea "die casting, die casting, centrifugal casting" li loketse tlhahiso ea bongata ka bongata bo boholo ka lebaka la lisebelisoa tse turang le lisebelisoa.

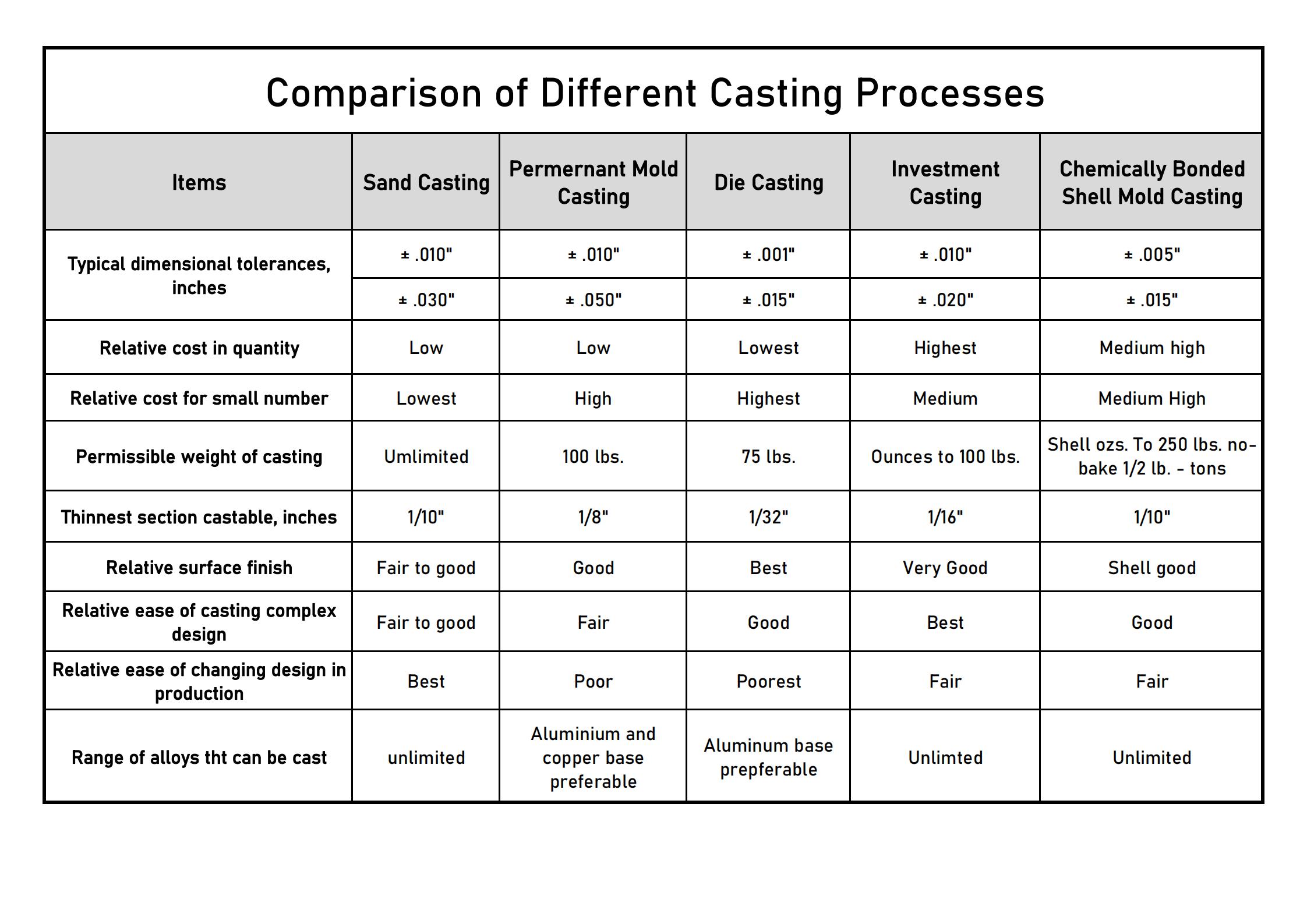

3- Dimensional Tolerances le Surface Quality Count

Ts'ebetsong ea ho khetha mokhoa oa ho lahla thepa ea tšepe ea tšepe, ho nepahala ha dimensional le boleng ba bokaholimo le tsona li bohlokoa. Ho khetha amokhoa o nepahetseng oa ho lahlae tla fokotsa tlhokeho ea ho etsa machining, leha e se na machining. Sena se hloka hore ho nahanoe ka botlalo ho leka-lekana pakeng tsa keketseho ea litšenyehelo tsa ho lahlela le phokotso ea machining. Ho ipapisitsoe le boiphihlelo ba rona ba lilemo tse ngata, baenjiniere ba k'hamphani ea rona ba ka u khethela mokhoa o loketseng le o nang le chelete e ngata bakeng sa hau.

Nako ea poso: Jan-28-2021