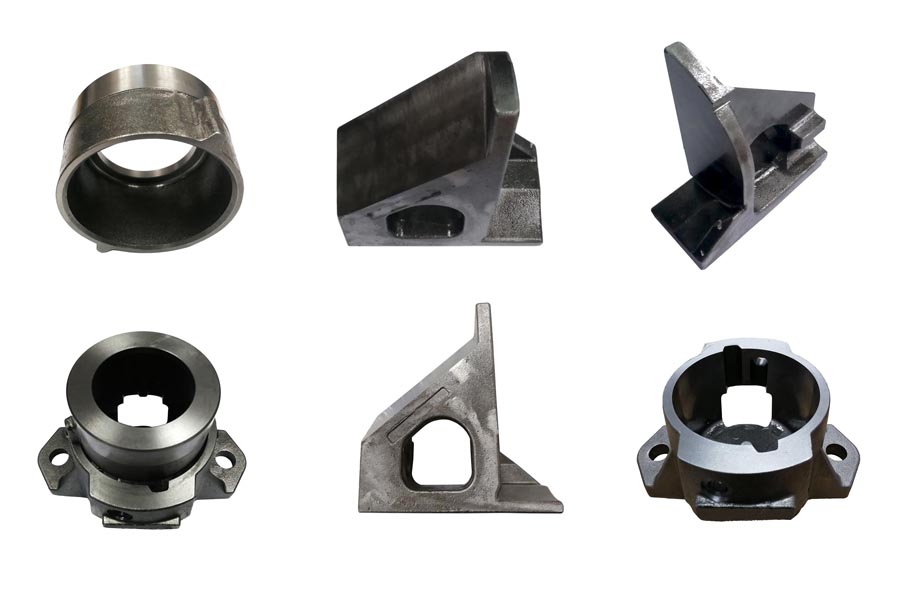

Ho RMC Casting Foundry, re amohelaresin e koahetsoeng ke hlobo ea lehlabathe(ha ho na mokhoa oa ho baka le oa ho ithatafatsa) ho lahlela koporo, boronse le lisebelisoa tse ling tsa koporo.

Lisebelisoa tsa koporoli sebelisoa haholo tšimong ea valve le pompo ka lebaka la ts'ebetso e babatsehang ea lisebelisoa tsa koporo. Ho RMC Foundry, re hlahisa lihlahisoa tsali-castings tsa koporoka ho lahla lehlabathe le letala, lehlabathe le koahetsoeng ka resin;ho kenya cheletele bakeng sa lisebelisoa tse kholo tsa koporo, re boetse re amohela mokhoa o lahlehileng oa ho lahlela foam le vacuum casting. Ka kakaretso, li-castings tsa koporo tse hlahisoang ke ho lahla lehlabathe ke tsona tse ka sehloohong setsing sa rona.

Alloy ea koporo e nang le zinki joalo ka karolo ea mantlha ea alloying hangata e bitsoa koporo. Copper-zinc binary alloy e bitsoa koporo e tloaelehileng, 'me koporo ea ternary, quaternary kapa multi-element e thehoa ka ho eketsa karolo e nyenyane ea lintho tse ling motheong oa koporo-zinki alloy e bitsoa koporo e khethehileng. Cast brass e sebelisoa ho hlahisa koporo bakeng sa li-castings. Li-castings tsa Brass li sebelisoa haholo indastering ea ho etsa mechine, li-valve le lipompo, likepe, lifofane, likoloi, kaho le likarolo tse ling tsa indasteri, tse nang le boima bo itseng ka thepa e boima ea tšepe e se nang ferrous, ho etsa letoto la koporo.

Ha ho bapisoa le koporo le boronse, ho qhibiliha ho tiileng ha zinki ka koporo ho hoholo haholo. Tlas'a tekano e tloaelehileng ea mocheso, hoo e ka bang 37% ea zinki e ka qhibiliha ka koporo, 'me hoo e ka bang 30% ea zinki e ka qhibiliha sebakeng sa as-cast, ha tin bronze. ka koporo ke feela 5% ho 6%. Karolo e kholo ea solubility e tiileng ea boronse ea aluminium ka koporo ke 7% ho isa ho 8%. Ka hona, zinki e na le phello e ntle e tiileng ea ho matlafatsa koporo. Ka nako e ts'oanang, likarolo tse ngata tsa alloying li ka boela tsa qhibiliha ka koporo ho likhato tse sa tšoaneng , Ho feta moo ho ntlafatsa thepa ea eona ea mechine, e le hore koporo, haholo-holo koporo e khethehileng e na le litšobotsi tsa matla a phahameng. Theko ea zinki e tlase ho feta ea aluminium, koporo le thini, 'me e na le lisebelisoa tse ngata. Palo ea zinki e kenyelletsoeng ka koporo e batla e le khōlō, kahoo theko ea koporo e tlaase ho feta tin bronze le aluminium bronze. Brass e na le mocheso o fokolang oa ho tiisa, metsi a matle, le ho qhibiliha ha bonolo.

Hobane koporo e na le litšobotsi tse boletsoeng ka holimo tsa matla a phahameng, theko e tlaase le ts'ebetso e ntle ea ho lahla, koporo e na le mefuta e mengata, tlhahiso e kholoanyane le ts'ebeliso e pharaletseng ho feta boronse ba tin le boronse ba aluminium ka li-alloys tsa koporo. Leha ho le joalo, khanyetso ea ho roala le ho hanyetsa ha kutu ea koporo ha e ntle joaloka boronse, haholo-holo ho hanyetsa kutu le ho roala ha koporo e tloaelehileng e batla e le tlaase. Ke feela ha likarolo tse ling tsa alloy li eketsoa ho theha koporo e khethehileng e fapaneng, ts'ebetso ea eona ea ho hanyetsa le ho hanyetsa ts'ebetso e ntlafalitsoe le ho ntlafatsoa.

Joalo ka mofuta oa lehlabathe le ithatafatsang, lehlabathe la no-bake furan resin le sebelisoa haholo bakeng sa ho lahla lehlabathe la tšepe le ductile iron casting. Bokaholimo ba hlobo ea lehlabathe bo ne bo tla tiisoa ho ba boemong bo thata ka mor'a hore seaparo se chesoe. Ka hona, mokhoa oa ho lahla lehlabathe la furan resin o ne o ka sebelisoa ho hlahisa likarolo tsa tšepe tse boholo bo bohareng le tse kholo, ho tloha ho mashome a lik'hilograma ho isa ho lithane tse mashome. Ka boleng bo botle ba bokaholimo, mamello e matla haholoanyane le bofokoli bo fokolang ba ho lahla, lits'ebetso tsa ho lahla lehlabathe la furan resin li ka sebelisoa ho hlahisa likarolo tse rarahaneng tsa ho lahla.

RMC e sebelisa mokhoa oa ho lahla lehlabathe la No-bake bakeng sa ho hlahisa litšepe tsa tšepe, li-castings tsa tšepe e sa hloekang, li-ductile iron castings, le li-castings tsa tšepe tse bohlooho. Ts'ebetsong ea No-Bake, hlobo ea lehlabathe e entsoe ka lehong kapa mohlala oa tšepe. Lehlabathe la lijo-thollo tse ntle le kopantsoe le sekontiri sa resin ka har'a motsoako oa lehlabathe le lebelo le holimo ebe o theohela ka lebokoseng le nang le mohlala. Metsotso e seng mekae hamorao, motsoako o kopanyang lehlabathe oa ithatafatsa 'me hlobo e ntšoa ho tloha mefuteng. Li-Sand Cores bakeng sa ho theha mohaho oa ka hare oa li-castings li etsoa ka mokhoa o ts'oanang ka nako e le 'ngoe. Ka mor'a hore li-cores le li-molds tsa ka ntle li bokelloe, lia koaloa 'me li lokiselitsoe ho tšela tšepe. Lisebelisoa tse ling, tse kang li-castings tsa tšepe tsa ductile, li hloka phekolo e khethehileng ea tšepe pele e tšolloa. Ts'ebetso ea ho lahla ha No-Bake e feto-fetoha haholo kaha e lumella li-castings tsa tšepe le li-castings tsa tšepe hore li bolokehe ho mamellana hantle ha li ntse li khona ho sebetsana le boholo ba likarolo ho tloha ho ligrama tse mashome ho ea ho lithane tse mashome.

Mehato ea ho No Bake Shell Casting Process:

No bake ke mokhoa oa ho lahla o kenyelletsang tšebeliso ea lik'hemik'hale tse kopanyang ho kopanya lehlabathe le bōpiloeng. Lehlabathe le fetisetsoa setsing sa ho tlatsa hlobo ho itokisetsa ho tlatsa hlobo. Motsoako o sebelisoa ho kopanya lehlabathe le motsoako oa lik'hemik'hale le catalyst. Ha lehlabathe le tsoa ka har'a motsoako, sekontiri se qala tšebetso ea lik'hemik'hale ea ho thatafala. Mokhoa ona oa ho tlatsa hlobo o ka sebelisoa bakeng sa halofo e 'ngoe le e' ngoe ea hlobo (ho sebetsana ka katleho le ho hula). Halofo ka 'ngoe ea hlobo e ntan'o kopanngoa ho etsa hlobo e matla le e teteaneng. Joale rollover e sebelisoa ho tlosa halofo ea hlobo ho tloha lebokoseng la mohlala. Ka mor'a hore lehlabathe le behoe, ho ka sebelisoa ho hlatsoa hlobo. Li-cores, haeba ho hlokahala, li behiloe ka har'a hula 'me cope e koetsoe holim'a li-cores ho tlatsa hlobo. Letoto la likoloi tse tšoarang hlobo le li-conveyors li tsamaisa hlobo sebakeng sa ho tšeloa. Hang ha e tšeloa, hlobo e lumelloa ho pholile pele e sisinyeha. Mokhoa oa ho sisinya o kopanyelletsa ho pshatla lehlabathe le bōpiloeng hole le ho lahla. E ntan'o tsoela pele ho ea sebakeng sa ho qetela bakeng sa ho tlosoa ha risepe, ho qetela le ho phethela. Likaroloana tse robehileng tsa lehlabathe le bōpiloeng li senyeha hape ho fihlela lehlabathe le khutlisetsoa boholong ba lijo-thollo. Lehlabathe joale le ka khutlisoa hore le sebelisoe hape nakong ea ho lahla kapa la tlosoa hore le lahloe. Thermal reclamation ke mokhoa o sebetsang ka ho fetesisa, o felletseng oa ho se lokise lehlabathe la ho baka.

| Lisebelisoa tsa Shell Mold Casting ho RMC Foundry | |

| Metal & Alloys | Sehlopha se Tsebahalang |

| Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ts'epi ea Ductile (Nodualar) | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Tšepe ea Carbon | C20, C25, C30, C45 |

| Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Ts'epe e sa beng le mabali | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Pula e thatafatsa Stainless Steel, Duplex Stainless Steel |

| Lisebelisoa tsa Aluminium | ASTM A356, ASTM A413, ASTM A360 |

| Lisebelisoa tsa koporo / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, le GB | |