Lihlahisoa tsa OEM tse tloaelehileng tsa vacuum tsa tšepe e bohlooho le spheroidal graphite (SG) ductile nodular cast iron e nang le phekolo ea mocheso, phekolo ea holim'a metsi le tšebeletso ea mochine oa CNC.

Vacuum Casting e boetse e bitsoa Negative Pressure Tial Casting, Fokotsa Khatello ea Khatello kapa V Process Casting. Vacuum khatello ea ho lahla ho hloka tšebeliso ea lisebelisoa tsa ho ntša moea ho ntša moea ka hare ho hlobo ea ho lahla, ebe o sebelisa phapang ea khatello pakeng tsa ka hare le ka ntle ho hlobo ho koahela filimi e futhumetseng ea polasetiki holim'a paterone le thempleite. The casting hlobo e tla ba matla ka ho lekaneng ho mamella tšepe e qhibilihisitsoeng nakong ea ho etsoa. Ka mor'a ho fumana hlobo ea vacuum, tlatsa lebokose la lehlabathe ka lehlabathe le omeletseng ntle le se tlamella, 'me u tiise bokaholimo ba hlobo ea lehlabathe ka filimi ea polasetiki, e lateloe ke vacuum ho tiisa lehlabathe. Ka mor'a moo, tlosa hlobo, beha li-cores tsa lehlabathe, koala hlobo ho etsa hore ntho e 'ngoe le e' ngoe e loketse ho tšolloa. Qetellong, ho lahla ho fumanoa ka mor'a hore tšepe e qhibilihisitsoeng e pholile ebe e tiisa.

| Lahlehileng Foam Casting vs Vacuum Casting | ||

| Ntho | Ho Lahla Foam e Lahlehileng | Vacuum Casting |

| Li-castings tse loketseng | Li-castings tse nyane le tse mahareng tse nang le likheo tse rarahaneng, joalo ka block block, sekoaelo sa enjine | Li-casting tse mahareng le tse kholo tse nang le likheo tse fokolang kapa tse se nang letho, joalo ka litekanyo tsa tšepe tse entsoeng ka tšepe, li-axle tsa tšepe tse entsoeng ka tšepe. |

| Lipaterone le Lipoleiti | Mekhoa ea foam e entsoeng ka li-moldings | Setšoantšo se nang le lebokose la ho hula |

| Lebokose la Lehlabathe | Mahlakoreng a ka tlase kapa a mahlano | Mahlakore a mane a qeta kapa a nang le phala ea ho tsoa |

| Filimi ea polasetiki | Sekoahelo se ka holimo se tiisitsoe ka lifilimi tsa polasetiki | Mahlakore 'ohle a likarolo tse peli tsa lebokose la lehlabathe a tiisitsoe ka lifilimi tsa polasetiki |

| Lisebelisoa tsa ho roala | Pente e entsoeng ka metsi e nang le seaparo se teteaneng | Pente e entsoeng ka joala e nang le seaparo se tšesaane |

| Lehlabathe la ho Bopa | Lehlabathe le omeletseng le thata | Lehlabathe le omeletseng le letle |

| Vibration Molding | 3D Vibration | Tšisinyeho e emeng kapa e tšekaletseng |

| Ho tshela | Ho tsholoha hampe | Ho tsholoha hampe |

| Mokhoa oa Lehlabathe | Fokotsa khatello e mpe, phetla lebokose ho theola lehlabathe, ebe lehlabathe le sebelisoa hape | Fokotsa khatello e mpe, joale lehlabathe le omeletseng le oela skrineng, 'me lehlabathe le tsosolosoa |

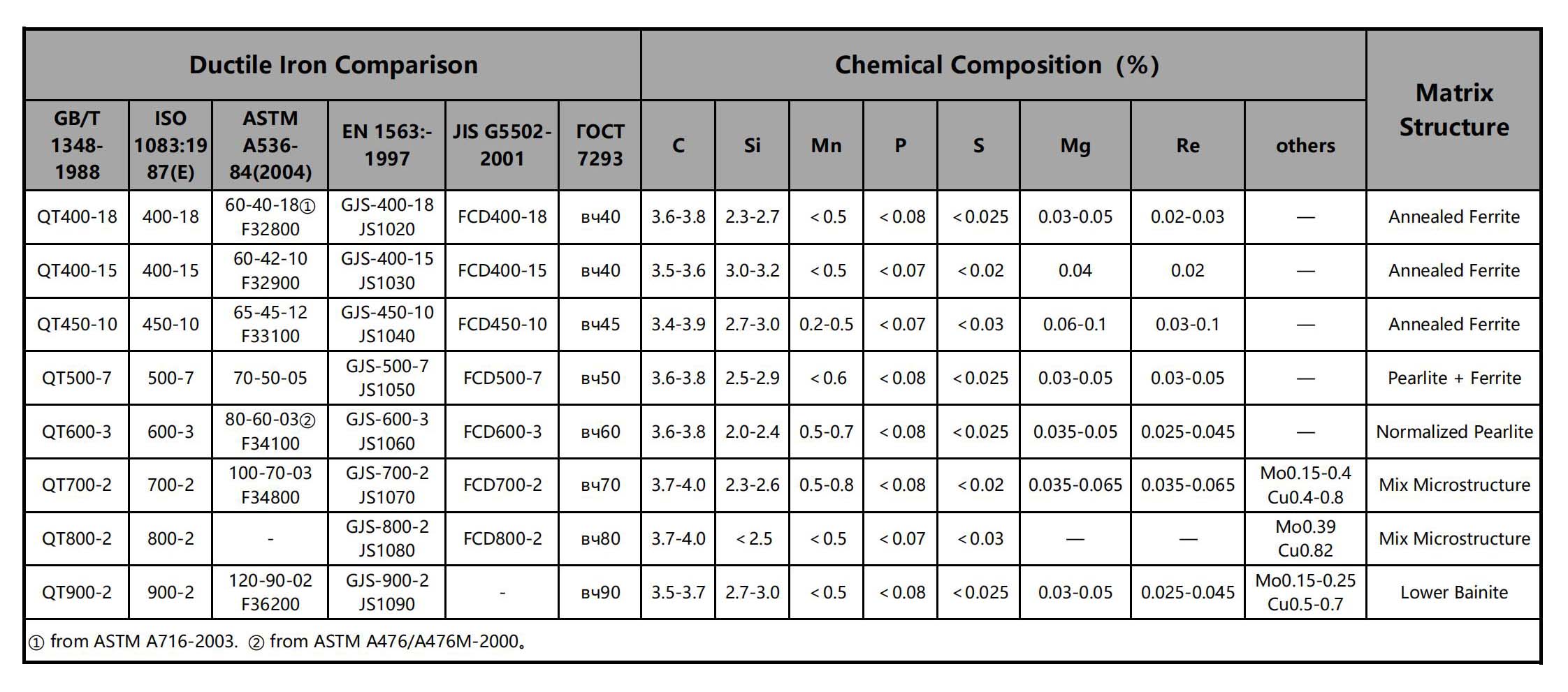

Ductile cast iron, eo hape e bitsoang nodular cast iron, spheroidal graphite cast iron kapa feela SG iron for short, emela sehlopha sa tšepe ea tšepe. Nodular cast iron e fumana nodular graphite ka phekolo ea spheroidization le inoculation, e leng ho ntlafatsa ka katleho thepa ea mochine oa tšepe ea tšepe, haholo-holo polasetiki le ho tiea, e le ho fumana matla a phahameng ho feta carbon steel.

Lisebelisoa tsa tšepe tsa ductile li na le ts'ebetso e ntle ea ho monya ho ts'oenyeha ho feta carbon steel, athe li-casting tsa carbon steel li na le cheseletso e ntle haholo. 'Me ho isa bohōleng bo itseng, li-ductile iorn castings li ka ba le litšoantšiso tse ling tsa ho roala le mafome. Kahoo ho lahla tšepe ea ductile ho ka sebelisoa bakeng sa matlo a pompo kapa lisebelisoa tsa phepelo ea metsi. Leha ho le joalo, re ntse re hloka ho etsa mehato ea ho li sireletsa hore li se ke tsa apara le ho rusa.

Tšepe ea ductile hase ntho e le 'ngoe empa ke karolo ea sehlopha sa lisebelisoa tse ka hlahisoang ho ba le mefuta e mengata ea thepa ka ho laola microstructure. Tšobotsi e tloaelehileng e hlalosang sehlopha sena sa lisebelisoa ke sebōpeho sa graphite. Ka litšepe tsa ductile, graphite e ka sebōpeho sa li-nodule ho e-na le li-flakes joalokaha e le ka tšepe e bohlooho. Sebopeho se hlabang sa li-flakes tsa graphite se etsa hore ho be le lintlha tsa khatello ea kelello ka har'a matrix ea tšepe le sebōpeho se chitja sa li-nodule tse fokolang haholo, kahoo li thibela ho thehoa ha mapetsong le ho fana ka ductility e ntlafetseng e fanang ka alloy lebitso la eona. Ka kakaretso, haeba tšepe ea ductile e ka finyella litlhoko tsa hau, tšepe ea ductile e ka ba khetho ea hau ea pele, ho e-na le tšepe ea carbon bakeng sa li-castings tsa hau.