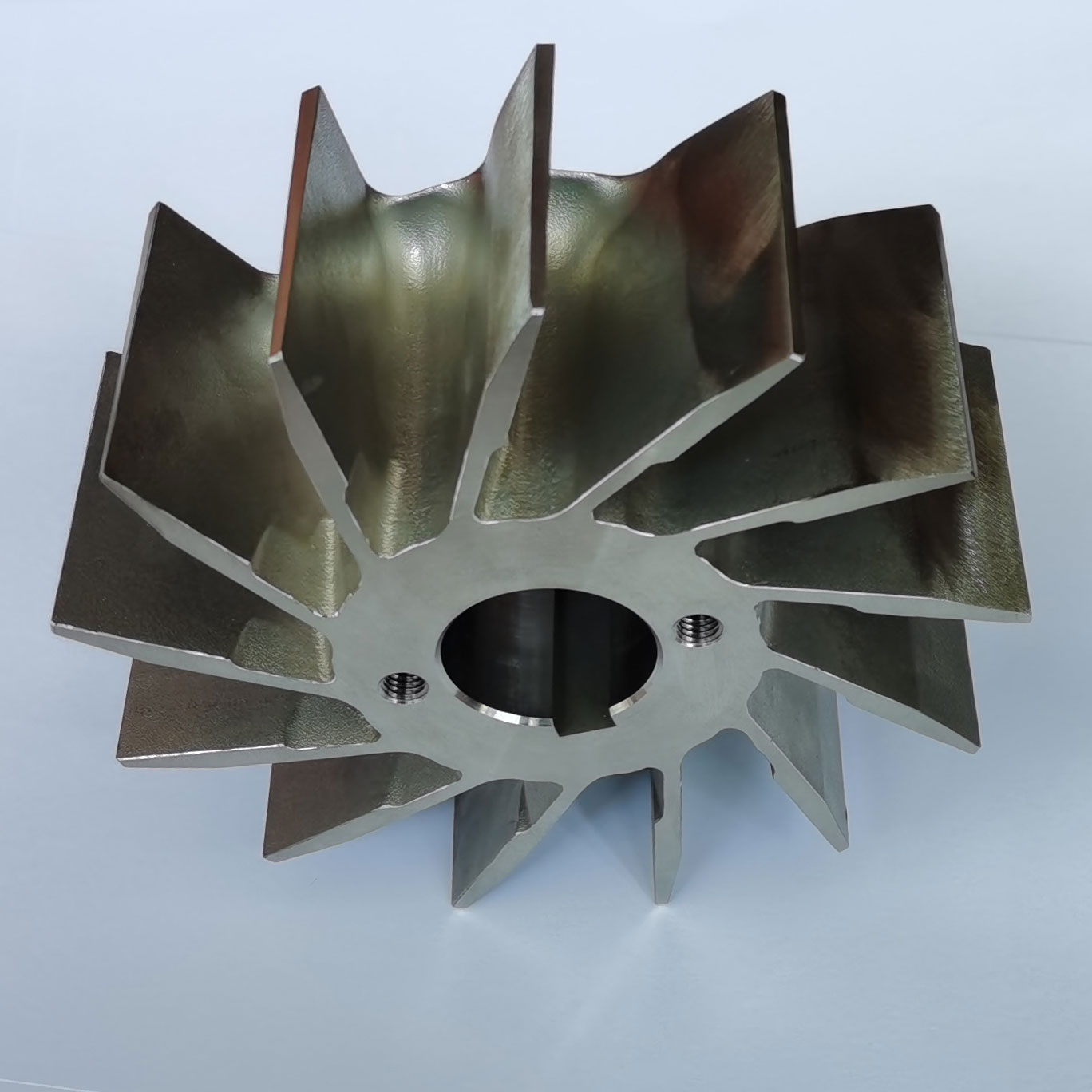

CF8M lahla tšepe e sa jeleng paate e bulehileng bakeng sa pompo ea centrifugal ka ho lahla matsete,Mechine ea CNCle ho leka-lekanya ho matla.

CF8M ke tšepe e sa hloekang ea austenitic e koahetsoeng ke ASTM A351, ASTM A743 le ASTM A744 standard. CF8M e lekana le SS 316/F 316 le Chinese Standard 0Cr17Ni12Mo2. CF8M ke molybdenum e nang le phetoho ea CF8 alloy 'me e lekana le AISI 316 Stainless steel e entsoeng. Ho ba teng ha molybdenum ho eketsa khanyetso e akaretsang ea kutu le khanyetso ea ho koaheloa ke li-chloride. Alloy e sebelisoa maemong a asiti e bonolo le alkaline le bakeng sa ho sebetsana le citric, oxalic le phosphoric acid. Stainless steel CF8M hangata e tšoana le SS 316, F 316 le TP 316. Empa ba hlalosoa ka litekanyetso tse fapaneng, 'me thepa ea bona ea lik'hemik'hale le ea mechine e fapane hanyane hape. CF8M e hlalosoa ho ASMT A351, ASMT A743 le ASTM A744, e leng molemong oa ho lahla feela. SS 316 e hlalosoa ho ASTM A240 le ASTM A276, ke bakeng sa poleiti, lakane, likhoele kapa litšepe tse se nang tšepe. Sehlopha se seng se rehiloe lebitso la F316, e tsoang ho ASTM A182 bakeng sa likarolo tse entsoeng feela. TP316 e tla fumanoa ho ATSTM A376 bakeng sa phala feela. Lisebelisoa tsa mantlha tsa sekoaelo sa tšepe e sa hloekang ea CF8M: li-impellors, li-propeller, li-casings tsa pompo, 'mele oa li-valve le lipoleiti tsa khatiso. Phekolo e tloaelehileng ea mocheso bakeng sa CF8M ke Tharollo e tiileng ka ho futhumatsa ho feta 1900 °F (1040 °C), e tšoara nako e lekaneng ebe e tima ka metsing kapa e pholile ka potlako ka mekhoa e meng.

| Lintlha tsa Tekheniki tsa ho Lahlela Matsete ho RMC | |

| R&D | Software: Solidworks, CAD, Procast, Pro-e |

| Nako ea Ketapele bakeng sa Nts'etsopele le lisampole: matsatsi a 25 ho isa ho a 35 | |

| Tšepe e qhibilihisitsoeng | Ferritic Stainless Steel, Martensitic Stainless Steel,Austenitic tšepe e sa hloekang, Pula e thatafatsa tšepe e sa hloekang, Duplex Stainless Steel |

| Tšepe ea K'habone, Tšepe ea Alloy, Tšepe ea Sesebelisoa, Tšepe e Thibela Mocheso, | |

| Alloy-base ea Nickle, Aluminium Alloy, Copper-base Alloy, Cobalt-base Alloy | |

| Metal Standard | ISO, GB, ASTM, SAE, GOST EN, DIN, JIS, BS |

| Thepa bakeng sa Kaho ea Shell | Silica Sol (Silika e Natehileng) |

| Khalase ea Metsi (Sodium Silicate) | |

| Metsoako ea Silica Sol le Glass ea Metsi | |

| Tekheniki Parameter | Boima ba sekhechana: 2 gram ho isa ho 200 lik'hilograma |

| Boemo bo Phahameng: 1,000 mm bakeng sa Diameter kapa Bolelele | |

| Min Botenya ba Lebota: 1.5mm | |

| Ho Lahlela Bokhopo: Ra 3.2-6.4, Bokhopo ba Machining: Ra 1.6 | |

| Mamello ea ho Lahlela: VDG P690, D1 / CT5-7 | |

| Mamello ea Machining: ISO 2768-mk/IT6 | |

| Inner Core: Ceramic Core, Urea Core, Metsi a Soluble Wax Core | |

| Kalafo ea Mocheso | Normalizing, Tempering, Quenching, Annealing, Tharollo, Carburization. |

| Phekolo ea Bokaholimo | Ho penta, ho phatloha ka lehlabathe / ho thunngoa, ho cheka zinki, ho pata ka nikeli, kalafo ea oxidation, phosphating, ho penta ka phofo, Geormet, Anodizing. |

| Dimension Testing | CMM, Vernier Caliper, Ka hare ho Caliper. Depth Gage, Height Gage, Go/No go go Gage, Litokiso tse Khethehileng |

| Tlhahlobo ea Lik'hemik'hale | Tlhahlobo ea Lik'hemik'hale (Lik'hemik'hale tse 20), Tlhahlobo ea Bohloeki, Tlhahlobo ea X-ray Radiographic, Analyzer ea Carbon-Sulfur |

| Tlhahlobo ea 'Mele | Matla a Teka-tekano, Ponahalo e tsitsitseng, Thepa ea Mechini (Bothata, Matla a Puno, Matla a Tsitlellang), Elongation |

| Bokhoni ba Tlhahiso | Ho feta lithane tse 250 ka khoeli, lithane tse fetang 3,000 ka selemo. |

Sebopeho sa Lik'hemik'hale sa CF8M Cast Cast Stainless Steel:

Khabone: 0.08 max

Manganese: 1.50 max

silicon: 1.50 max

Sebabole: 0.040 max

Phosphorus: 0.040 max

Chromium: 18.0-21.0

Nickel: 9.0-12.0

Molybdenum: 2.0-3.0

Mechanical Properties of CF8M Cast Stainless Steel:

Matla a Tensile: min 70 ksi (485 Mpa)

Matla a ho Hlaha: min 30 ksi (205 Mpa)

Elongation ka 2 inch. kapa 50 mm: min 30.0%

Hobaneng ba Bitsoa CF8M?

Ho ea ka tlhaloso, lengolo la pele la C le bolela tšebeletso eo e reretsoeng ho e sebelisa tšebeletsong e thibelang ho bola , empa ka linako tse ling e bolela tšebeliso ea CASTING hobane u tla fumana F 316 ho ASTM A 350 ( F = FORGE). Lengolo la bobeli F le bontša sebaka se lekanyelitsoeng sa alloy ho setšoantšo sa ternary sa tšepe-chromium-nickel (FeCrNi). Bakeng sa basebelisi ba tloaelaneng le setšoantšo, tlhaku ea bobeli e fana ka sesupo sa litaba tsa tšepe, nickel, le chromium, empa batho ba bangata ba tla tlameha ho fumana leseli la alloying ho tsoa ho lintlha tse itseng. Tlhaku ea boraro le ea bone 8M e emetse boholo ba khabone e lumelletsoeng ka likarolo tsa 0.01% (mohlala, CF8M e na le boholo ba 0.08% ea khabone)