Lihlahisoa tsa matsete a cobalt tse thehiloeng ho alloy tse tsoang Chaena ea mantlha e nang le kalafo ea mocheso le lits'ebeletso tsa mochini oa CNC

| Litšepe bakeng saTs'ebetso ea ho Lahlela Matseteho RMC | |||

| Sehlopha | China Kereiti | Sehlopha sa US | Jeremane Kereiti |

| Tšepe ea Carbon | ZG15, ZG20, ZG25, ZG35, ZG45, ZG55, Q235, Q345, Q420 | 1008, 1015, 1018, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1060, 1070, WC6, WCC, WCB, WCA, LCB | 1.0570, 1.0558, 1.1191, 1.0619, 1.0446, GS38, GS45, GS52, GS60, 1.0601, C20, C25, C30, C45 |

| Tšepe ea Alloy e tlase | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V | 1117, 4130, 4140, 4340, 6150, 5140, WC6, LCB, Gr.13Q, 8620, 8625, 8630, 8640, H13 | GS20Mn5, GS15CrNi6, GS16MnCr5, GS25CrMo4V, GS42CrMo4, S50CrV4, 34CrNiMo6, 50CrMo4, G-X35CrMo17, 1.1131, 1.0037, 1.0122, 1.2162, 1.2542, 1.6511, 1.6523, 1.6580, 3, 2, 1.713 1.7225, 1.7227, 1.7228, 1.7231, 1.7321, 1.8519, ST37, ST52 |

| Phahameng Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Tool Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Tšepe e Hanang Mocheso | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOLOY600, INCOLOLOY625 | 2.4815, 2.4879, 2.4680 | |

| Cobalt-base Alloy | UMC50, 670, Kereiti ea 31 | 2.4778 | |

Cobalt-based alloy ke motsoako o thata o ka mamellang mefuta e fapaneng ea ho roala, kutu le mocheso o phahameng oa oxidation. Li-alloys tse thehiloeng ho cobalt li thehiloe holim'a cobalt e le karolo ea mantlha, e nang le nickel e ngata, metsoako ea lik'hemik'hale e kang chromium, tungsten le lisebelisoa tse nyenyane tse kang molybdenum, niobium, tantalum, titanium, lanthanum, 'me ka linako tse ling tšepe. . Ho ea ka sebopeho se fapaneng sa motsoako, motsoako o thehiloeng ho cobalt o ka etsoa terata ea welding, 'me phofo e ka sebelisoa bakeng sa welding e thata holim'a holim'a metsi, ho fafatsa ka mocheso, ho cheselletsa ho fafatsa le mekhoa e meng, hape e ka etsoa ka li-castings. , forgings le likarolo phofo metallurgy. E khetholloa ke tšebeliso ea ho qetela, li-alloys tse thehiloeng ho cobalt li ka aroloa ka li-alloys tse sa thibeleng ho apara tse entsoeng ka cobalt, li-alloys tse nang le mocheso o phahameng oa cobalt le li-alloys tse thibelang ho bola ha cobalt. Maemong a tloaelehileng a ts'ebetso, ka bobeli ha li senyehe 'me ha li na mocheso o phahameng kapa ha li senyehe ebile ha li na kutu. Maemo a mang a ts'ebetso a ka boela a hloka mocheso o phahameng, ho roala le ho hanyetsa ho bola ka nako e le 'ngoe. Ha maemo a sebetsa a rarahane haholoanyane, melemo e totobetseng ea li-alloys tse thehiloeng ho cobalt.

Thepa ea Cobalt-Based Alloys

Li-carbides tse ka sehloohong tsa li-superalloys tse thehiloeng ho cobalt ke MC, M23C6 le M6C. Ka li-alloys tse thehiloeng ho cobalt, M23C6 e kenngoa pakeng tsa meeli ea lijo-thollo le li-dendrites nakong ea ho pholile butle. Li-alloys tse ling, M23C6 e ntle e ka theha eutectic e nang le matrix γ. Likaroloana tsa MC carbide li kholo haholo hore li ka ba le phello e kholo ho li-dislocation, ka hona phello e matlafatsang ho motsoako ha e hlake, ha li-carbide tse hasantsoeng hantle li na le phello e ntle ea ho matlafatsa. Li-carbides tse moeling oa lijo-thollo (haholo-holo M23C6) li ka thibela ho thella ha moeli oa lijo-thollo, ka hona ho ntlafatsa matla a mamello. The microstructure ea cobalt-based superalloy HA-31 (X-40) ke sekhahla se matlafatsang se qhalakaneng (CoCrW) 6 C-mofuta oa carbide. Mekhahlelo e haufi-ufi ea topological e hlahang ka har'a li-alloys tse ling tse thehiloeng ho cobalt, joalo ka sigma phase e kotsi mme e etsa hore alloy e brittle.

Ho tsitsa ha mocheso oa li-carbides ka li-alloys tse thehiloeng ho cobalt ho molemo. Ha mocheso o phahama, sekhahla sa khōlo ea carbide se tsamaea butle ho feta sekhahla sa kholo ea γ ka alloy e thehiloeng ho nickel, 'me mocheso oa ho qhibiliha hape ka har'a matrix o phahame (ho fihla ho 1100 ° C) . Ka hona, ha mocheso o phahama, motsoako o thehiloeng ho cobalt Matla a motsoako ka kakaretso a fokotseha butle-butle. Li-alloys tse thehiloeng ho cobalt li na le khanyetso e ntle ea mocheso oa mocheso. Lebaka leo ka lona li-alloys tse thehiloeng ho cobalt li phahametseng li-alloys tse thehiloeng ho nickel tabeng ena ke hore ntlha e qhibilihisang ea cobalt sulfide (e kang Co-Co4S3 eutectic, 877 ℃) e phahame ho feta ea nickel ( Ka mohlala, Ni-Ni3S2 eutectic (645 ° C) e phahame, 'me sekhahla sa ho hasana ha sebabole ka cobalt se tlase haholo ho feta sa ka 'Me hobane li-alloys tse ngata tse thehiloeng ho cobalt li na le lihlahisoa tse phahameng tsa chromium ho feta li-alloys tse thehiloeng ho nickel, li ka etsa lera le sireletsang la sulfate ea tšepe ea alkali (e kang Cr2O3 e sireletsang ke Na2SO4) holim'a motsoako , khanyetso ea oxidation ea li-alloys tse thehiloeng ho cobalt hangata e tlase haholo ho feta ea li-alloys tse thehiloeng ho nickel.

Ho fapana le li-superalloy tse ling, li-superalloys tse thehiloeng ho cobalt ha li matlafatsoe ke mohato o laetsoeng oa pula o tlamahaneng ka thata ho matrix, empa o entsoe ka matrix ea austenite fcc e 'nileng ea e-ba tharollo e tiileng e matlafalitsoeng le palo e nyane ea carbides e ajoang ka har'a matrix. Li-superalloy tse thehiloeng ho cobalt li itšetlehile haholo ka ho matlafatsa carbide. Likristale tse hloekileng tsa cobalt li na le sebopeho sa kristale se haufi le hexagonal (hcp) se ka tlase ho 417 ° C, se fetohang ho fcc ka mocheso o phahameng. E le ho qoba phetoho ena nakong ea tšebeliso ea li-superalloys tse thehiloeng ho cobalt, hoo e ka bang li-alloys tsohle tse thehiloeng ho cobalt li kenngoa ka nickel e le ho tsitsisa sebopeho ho tloha mocheso oa kamore ho ea ho mocheso o qhibilihisang. Li-alloys tse thehiloeng ho cobalt li na le kamano e bataletseng ea khatello ea maikutlo le mocheso, empa li bonts'a khanyetso e phahameng ea mocheso ho mocheso o ka holimo ho 1000 ° C ho feta mocheso o mong o phahameng.

Mocheso oa Mocheso oa Li-Alloys tse thehiloeng ho Cobalt

Boholo le kabo ea likaroloana tsa carbide le boholo ba lijo-thollo ka li-alloys tse thehiloeng ho cobalt li na le kutloelo-bohloko haholo ts'ebetsong ea ho lahla. E le ho finyella matla a hlokahalang a mamello le thepa ea mokhathala oa mocheso oa likarolo tse entsoeng ka cobalt-based alloy casting, mekhoa ea ho lahla e tlameha ho laoloa. Li-alloys tse thehiloeng ho cobalt li hloka phekolo ea mocheso, haholo-holo ho laola pula ea li-carbides. Bakeng sa li-alloys tse entsoeng ka cobalt, pele u etsa phekolo ea tharollo e tiileng ea mocheso o phahameng, hangata ka mocheso oa hoo e ka bang 1150 ° C, e le hore li-carbide tsohle tsa mantlha, ho kenyelletsa le li-carbides tsa mofuta oa MC, li qhibilihe ka tharollo e tiileng; joale, phekolo ea botsofali e etsoa ka 870-980 ° C. Etsa hore li-carbides li be le pula hape.

Mefuta e Tloaelehileng ea Li-Alloys tse thehiloeng ho Cobalt

Mefuta e tloaelehileng ea li-alloys tse tloaelehileng tsa mocheso o phahameng oa cobalt ke: 2.4778 (ho ea ka DIN EN 10295)Hayness 188, Haynes 25 (L-605), Alloy S-816, UMCo-50, MP-159, FSX-414, X -40, Stellite 6B, Grade 31, joalo-joalo, lihlahisoa tsa Sechaena ke: GH5188 (GH188), GH159, GH605, K640, DZ40M joalo-joalo.

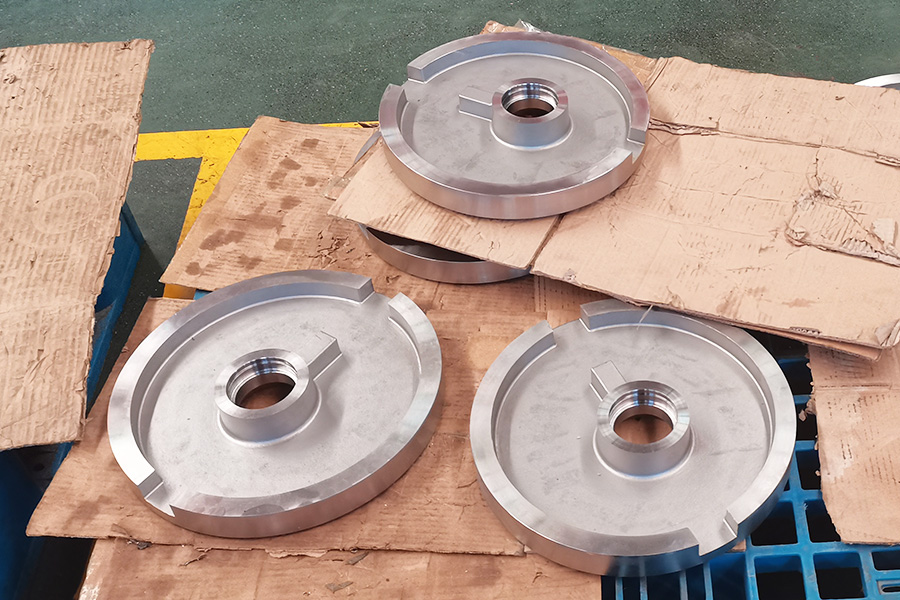

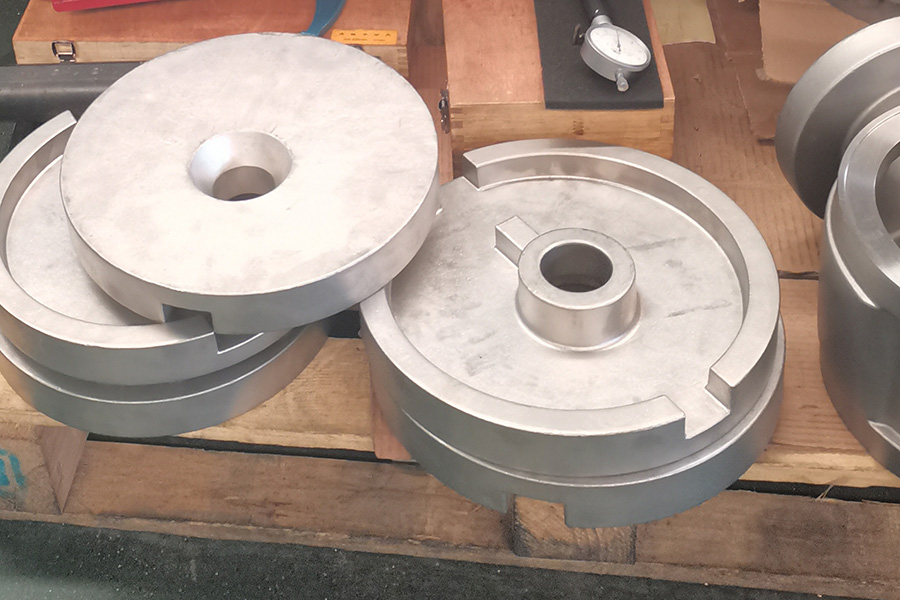

Lisebelisoa tsa Cobalt-based Alloy Castings

Ka kakaretso, li-superalloys tse thehiloeng ho cobalt ha li na mekhahlelo e matla ea ho matlafatsa. Leha matla a mocheso o mahareng a le tlase (ke 50-75% feela ea li-alloys tse thehiloeng ho nickel), li na le matla a holimo, li na le matla a holimo, li hanyetsa mokhathala oa mocheso, li hana ho soeufala, li khona ho chesehela hantle le ho hanyetsa mocheso oa kutu ho feta mocheso oa 980 ° C. Ka hona, li-alloy castings tse thehiloeng ho cobalt li loketse haholo ho etsa li-vane tsa tataiso le li-nozzle tse tataisang lienjineri tsa lifofane tsa lifofane, li-turbine tsa khase ea indasteri, li-turbine tsa khase ea metsing, le li-nozzles tsa enjine ea disele, jj.