Tšepe ea tšepe e sa khoneng ho bola, eo hape e bitsoang cast stainless steel, e bua ka tšepe ea alloy cast e bonts'ang khanyetso e matla ea ho bola mecheng ea litaba e fapaneng e senyang kapa tikolohong eo ho eona ho nang le kutu le lintho tse sebetsang hammoho.

| Maikutlo a Potlako bakeng sa Austenitic Stainless Steel | |

| Sebopeho se ka Sehloohong sa Lik'hemik'hale | Cr, Ni, C, Mo, Cu, Si, Nb, Ti |

| Tshebetso | Non-magnetic, toughness e phahameng, polasetiki e phahameng, matla a tlaase |

| Tlhaloso | Tšepe e sa hloekang e nang le sebopeho sa austenitic mocheso oa kamore |

| Mephato ya Moemedi | 304, 316, 1.4310, 1.4301, 1.4408 |

| Boikemisetso | E lokileng |

| Weldability | Ka kakaretso e ntle haholo |

| Lisebelisoa tse Tloaelehileng | Mechini ea lijo, Hardwares, Chemical Processing ... joalo-joalo |

Tšepe e sa hloekang e na le bonyane ba chromium ea 10.5%, e etsang hore e khone ho mamella maemo a mokelikeli a senyang le ho oxidation. Ha e khone ho senya 'me ha e senyehe, e fana ka bokhoni bo botle ba ho sebetsa, 'me e tsebahala haholo ka ponahalo ea eona e ntle. Mehaho ea matsete a tšepe e sa jeleng paate "e hana ho bola" ha e sebelisoa libakeng tse mokelikeli le mouoane o ka tlase ho 1200°F (650°C) le "tse thibelang mocheso" ha li sebelisoa ka holimo ho mocheso ona.

Austenitic tšepe e sa hloekange bua ka tšepe e sa hloekang e nang le sebopeho sa austenitic mocheso oa kamore. Austenitic stainless steel ke e 'ngoe ea lihlopha tse hlano tsa tšepe e sa hloekang ka sebopeho sa kristale (hammoho le ferritic, martensitic, duplex le pula e thata). Libakeng tse ling, tšepe e sa hloekang ea austentite e boetse e bitsoa 300 series stainless steel. Ha tšepe e na le hoo e ka bang 18% Cr, 8% -25% Ni, le hoo e ka bang 0.1% C, e na le mohaho o tsitsitseng oa austenite. Austenitic chromium-nickel tšepe e sa hloekang e kenyelletsa tšepe e tummeng ea 18Cr-8Ni le tšepe e phahameng ea Cr-Ni e ntlafalitsoeng ka ho eketsa litaba tsa Cr le Ni le ho eketsa Mo, Cu, Si, Nb, Ti le likarolo tse ling motheong ona. Austenitic stainless steel ha e na makenete ebile e na le boima bo phahameng le polasetiki, empa matla a eona a tlase, 'me ha ho khonehe ho e matlafatsa ka phetoho ea mohato. E ka matlafatsoa feela ke ho sebetsa ka serame. Haeba likarolo tse kang S, Ca, Se, Te li eketsoa, e na le thepa e ntle ea machinability.

Austenitic stainless steel e ka boela ea hlahisa li-castings. E le ho ntlafatsa metsi a tšepe e qhibilihisitsoeng le ho ntlafatsa ts'ebetso ea ho lahla, motsoako oa alloy oa tšepe ea tšepe o lokela ho lokisoa ka ho eketsa silicon, ho atolosa mefuta e mengata ea chromium le nickel content, le ho eketsa moeli o ka holimo oa ntho e sa hloekang sebabole.

Austenitic tšepe e sa hloekang e lokela ho ba le tharollo e tiileng pele e sebelisoa, e le ho eketsa tharollo e tiileng ea li-precipitates tse fapaneng tse kang carbides ka har'a matrix a austenite, ha e ntse e etsa homogenizing sebopeho le ho felisa khatello ea maikutlo, e le ho etsa bonnete ba hore ho hanyetsa Corrosion ho matla le ho feta. thepa ea mochine. Sistimi e nepahetseng ea kalafo ea tharollo ke ho pholisa metsi ka mor'a ho futhumatsa ka 1050~1150℃ (likarolo tse tšesaane le tsona li ka pholile moea). Mocheso oa phekolo ea tharollo o itšetlehile ka tekanyo ea motsoako oa tšepe: Molybdenum-free kapa low-molybdenum tšepe limaraka li lokela ho ba tlaase (≤1100 ℃), le limaraka tse phahameng tsa alloyed tse kang 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, joalo-joalo li lokela ho ba holimo ( 1080~1150) ℃).

Letlapa la tšepe la Austenitic 304, leo ho thoeng le tlisa matla a ho thibela mafome le ho hanyetsa ho bola, 'me le na le polasetiki e ntle haholo le e thata, e loketseng ho hatakela le ho theha. Ka boima ba 7.93 g / cm3, 304 tšepe e sa hloekang ke tšepe e sa hloekang e tloaelehileng haholo, e tsejoang hape e le 18/8 tšepe e sa hloekang indastering. Lihlahisoa tsa eona tsa tšepe li hanyetsa mocheso o phahameng 'me li na le thepa e ntle ea ho sebetsa, kahoo li sebelisoa haholo indastering le liindasteri tsa mokhabiso oa thepa ea ka tlung le indastering ea lijo le ea bongaka.

Kereiti e Tšoanang ea Stainless Steel | |||||||

| Lihlopha | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic le Ferritic Stainless Steel | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Kr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 KAROLO 13 | 405 S 17 | - | F.3111 | X6 KAROLO 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Kr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Kr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Stainless Steel | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Steel | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Lisebelisoa tsa Ferrous and Non-ferrous for Investment Casting, Last Wax Ts'ebetso:

- • Tšepe e Hlooho: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

- • Iron ea Ductile kapa Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

- • Lisebelisoa tsa tšepe: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo... joalo-joalo ka kopo.

- • Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 le sehlopha se seng sa tšepe e sa hloekang.

- • Koporo, Koporo e Khubelu, Bronze kapa tse ling tsa tšepe tse entsoeng ka koporo: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Lisebelisoa tse ling ho ea ka litlhoko tsa hau tse ikhethang kapa ho latela maemo a ASTM, SAE, AISI, ACI, DIN, EN, ISO, le GB

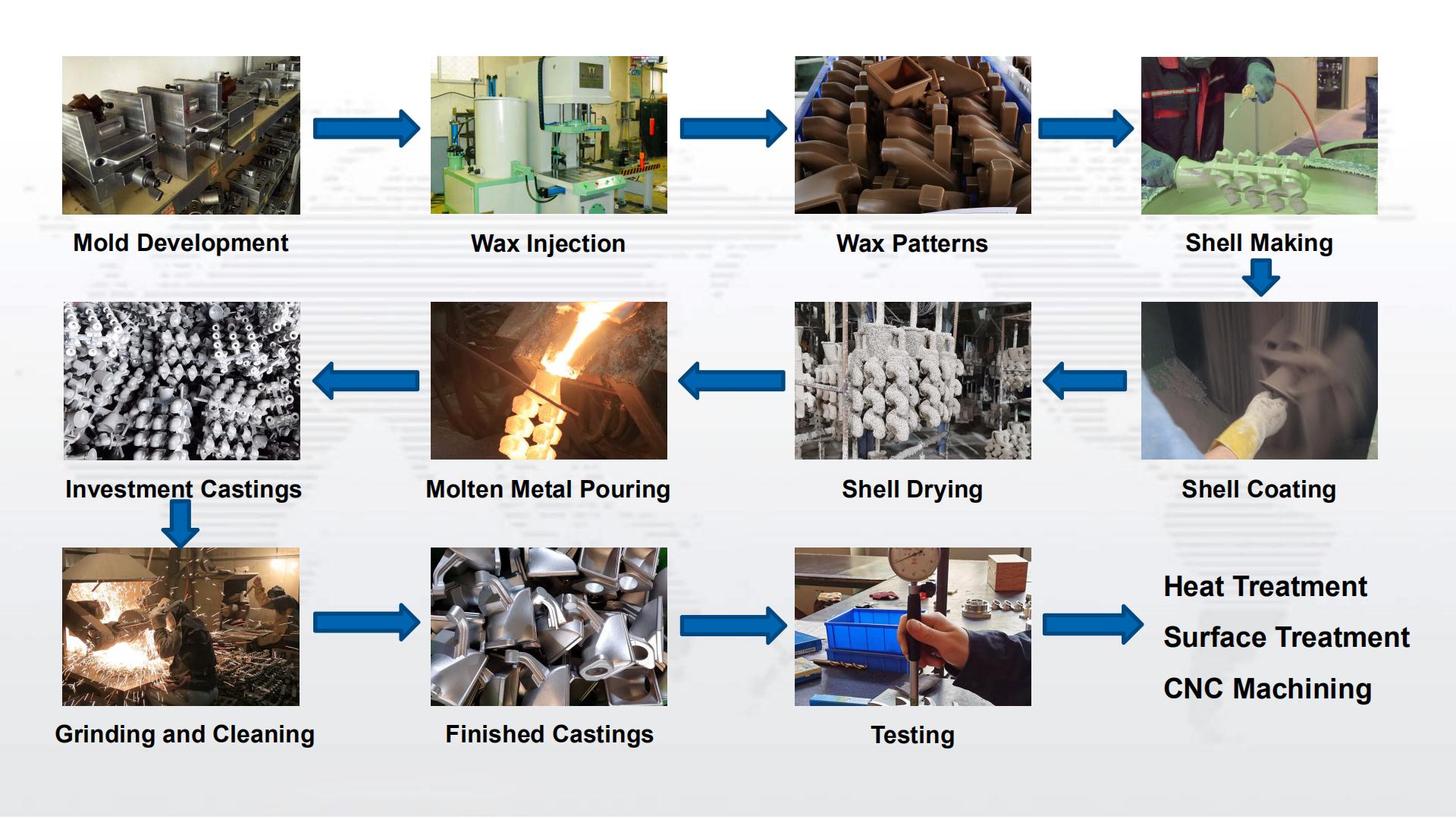

Mehato e amehang ts'ebetsong kapa ho lahleheloa ke boka ba linotsi ke:

- • Etsa mohlala oa boka kapa replica

- • Hlakola mohlala oa boka

- • Tsetela mohlala oa boka

- • Tlosa mohlala oa boka ka ho o chesa (ka har'a sebōpi kapa metsing a chesang) ho etsa hlobo.

- • Qobela tšepe e qhibilihisitsoeng ka har'a hlobo

- • Ho pholisa le ho Tiisa

- • Tlosa sprue ho li-castings

- • Qetella le ho bentša matsete a phethiloeng

Phekolo ea Mocheso ea AISI 316 Stainless Steel Castings:

Mocheso ho isa ho 1900 ° F (1040 ° C) bonyane, u tšoare nako e lekaneng, tima ka metsing kapa ho pholile ka potlako ka mekhoa e meng. AISI 316 e lekana le CF8M/F316 le Chinese Standard 0Cr17Ni12Mo2. AISI 314 ke molybdenum e nang le phetoho ea AISI 304 alloy 'me e lekana le CF8M Stainless steel e entsoeng. Ho ba teng ha molybdenum ho eketsa khanyetso e akaretsang ea kutu le khanyetso ea ho koaheloa ke li-chloride. Alloy e sebelisoa maemong a asiti e bonolo le alkaline le bakeng sa ho sebetsana le citric, oxalic le phosphoric acid.