Lihlahisoa tse tloahelehileng tsa Aluminium alloy ka homokhoa oa ho lahla lehlabatheleMechine ea CNC.

Mehato ea Ts'ebetso ea Tlhahiso ea Lehlabathe

1. Ho Etsa Lipaterone

Resin kapa lipaterone tsa aluminium li tla hlokahala bakeng sa ts'ebetso ea ho lahla lehlabathe le letala. Ntle le mekhoa, tlhahiso ea li-castings e ke ke ea khoneha. Ka linako tse ling, mekhoa ea mapolanka e ka sebelisoa bakeng sa tlhahiso ea palo e nyane, empa bakeng sa tlhahiso ea bongata, li-resin kapa aluminium li tla ba tse loketseng haholoanyane.

2. Molding Process

Mochini oa lehlabathe o motala o ne o ka etsoa ka mekhoa e meraro ka tloaelo, ho kenyeletsoa ho bopa ka matsoho, mochini o bopang le lisebelisoa tsa othomathike. Mokhoa oa ho bopa ka letsoho ke mokhoa o tloaelehileng oa ho bopa, empa o ntse o le teng ka lebaka la bokhoni ba oona ba ho etsa li-castings tse kholo ka litšenyehelo tse tlaase. Mokhoa oa mochini oa ho bopa o ka boloka basebetsi mme oa hlahisa li-castings tsa boleng bo holimo, empa ha o khone ho hlahisa li-castings tse kholo ka lebaka la moeli oa boholo ba mabokose a lehlabathe.

3. Tšepe e Qhibiliha le ho Tšela

Ho qhibiliha ho ka etsoa ka libopi tsa motlakase tsa maqhubu a mahareng, tse ka bolokang boleng bo botle le bo tsitsitseng ha bo bapisoa le libopi tsa setso.

4. Ho phatloha ha Lehlabathe le ho Sila

Ka mor'a hore litšepe tsa lehlabathe le letala li ntšoe liforong tsa lehlabathe, li tla fetisetsoa mehatong e latelang ea ho thunngoa kapa ho thunngoa ho tlosa lehlabathe le oxide ka ntle ho likarolo tsa ho lahla. Ebe ba sebetsang ba tla khaola, ba hloekise le ho sila lihlooho tsa li-gate, li-rivers, mela e arohaneng le likarolo tse bohale.

Ts'ebetso e tsoelang pele joalo ka kalafo ea mocheso, mochini o nepahetseng le kalafo ea bokaholimo e tla tsoela pele haeba litšoantšo kapa basebelisi ba ho qetela ba hloka.

Aluminium le li-alloys tsa eona li ne li ka lahleloa 'me tsa tšeloa ka khatello e phahameng ea lefu, ho lahlela lefu la khatello e tlase, ho lahlela matla a khoheli, ho akhela lehlabathe, ho lahla matsete lefoam e lahlehileng. Hangata, li-aluminium alloy castings li na le boima bo fokolang empa li rarahane le bokaholimo bo betere.

Seo re se Lahlelang Aluminium Alloy ka Mokhoa oa ho Lahlela Lehlabathe:

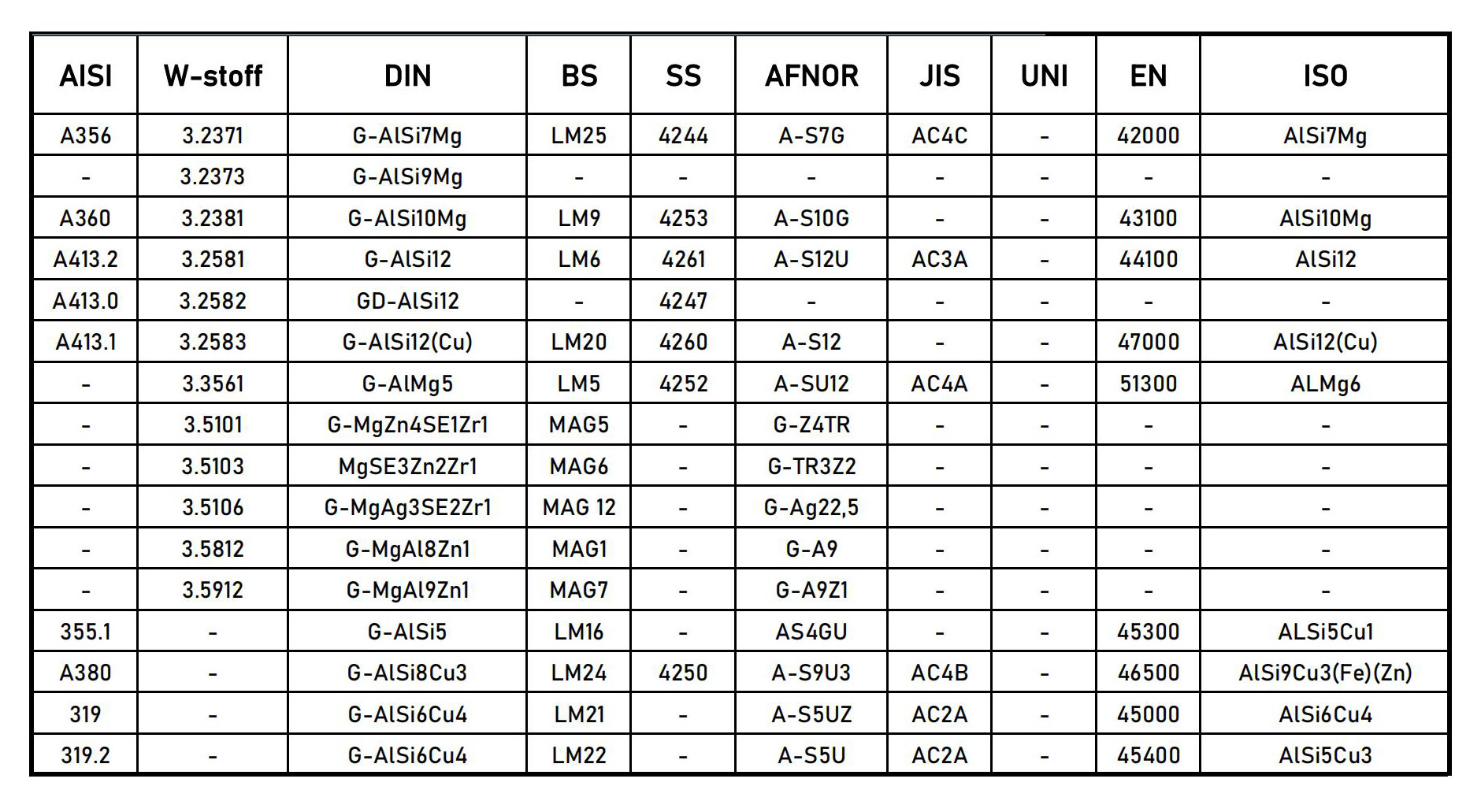

• Cast Aluminium Alloy ka China Standard: ZL101, ZL102, ZL104

• Cast Aluminium Alloy ke USA Stardard: ASTM A356, ASTM A413, ASTM A360

• Cast Aluminium Alloy ke li-Starndards tse ling: AC3A, AC4A, AC4C, G-AlSi7Mg, G-Al12

| Kopantsoeng | Mokhatlo oa Aluminium | Matla BHN | Matla a ho qetela, MPa | Kotulo Matla, MPa | Modulus ea elasticity, GPA | Mokhathala Matla, MPa |

| A03550 | AA355.0 | 75-105 | 255 | 185 | 70.3 | 69.0 |

| A03600 | AA360.0 | 75.0 | 300 | 170 | 71.0 | 138.0 |

| A03800 | AA380.0 | 80.0 | 317 | 159 | 71.0 | 138.0 |

| A03830 | AA383.0 | 75.0 | 310 | 152 | / | 145.0 |

| A03840 | AA384.0 | 85.0 | 331 | 165 | / | 140.0 |

| A03900 | AA390.0 | 120.0 | 280 | 240 | 81.2 | 140.0 |

| A04130 | AA413.0 | 80.0 | 296 | 145 | 71.0 | 130.0 |

| A04430 | AA443.0 | 30-60 | 145 | 48.3 | 71.0 | / |

| A05180 | AA518.0 | 80.0 | 310 | 193 | 69.0 | 160.0 |

Melemo ea Aluminium Alloy Castings:

• Ts'ebetso ea ho lahla e tšoana le ea li-castings tsa tšepe, empa thepa e amanang le mochini e fokotseha haholo ha botenya ba lebota bo ntse bo eketseha.

• Botenya ba marako ha boa lokela ho ba bo boholo haholo, 'me likarolo tse ling tsa sebopeho li tšoana le tsa li-castings tsa tšepe.

• Boima bo bobebe empa sebopeho se rarahaneng

• Litšenyehelo tsa ho lahlela ka kg ea li-castings tsa aluminium li phahame ho feta tsa tšepe le tšepe ea tšepe.

• Haeba e hlahisoa ka mokhoa oa "die casting", theko ea hlobo le mohlala e tla ba holimo haholo ho feta mekhoa e meng ea ho lahla. Ka hona, li-casting tsa aluminium tsa die casting li tla ba tse loketseng bakeng sa ho lahlela ka bongata bo boima.

| Sebopeho se Tloaelehileng sa Lik'hemik'hale sa Investment Casting Aluminium Alloy ka Litlhaloso tsa Amerika Leboea | ||||||||||||||

| Alloy Grade | Tlhaloso | Al | Cu | Si | Zn | Mg | Cr | Fe | Mn | Ti | Ag | Be | Ni | P |

| A356-T6 | AMS 4218 | Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.25-0.45 | - | 0.20 | 0.10 | 0.20 | - | -- | - | - |

| A357 | AMS 4219 | Bal | 0.20 | 6. 5 - 7. 5 | 0.10 | 0.40-.70 | - | 0.20 | 0.10 | 0.04-0.20 | - | 0.04-0.07 | - | - |

| F 357 | AMS 4289 | Bal | 0.20 | 6.5-7.5 | 0.10 | 0.40-.70 | - | 0.10 | 0.10 | 0.04-0.20 | - | 0.002 | - | - |

| E 357 | AMS 4288 | Bal | - | 6.5-7.5 | 0.10 | 0.55-0,60 | - | 0.10 | 0.10 | 0.10-0.20 | - | 0.002 | - | - |

| A201 | AMS 4229 | Bal | 4.0-5.0 | 0.05 | - | 0.15-0,35 | - | 0.10 | 0.20-0.34 | 0.15-0,35 | 0.40-1.0 | - | - | - |

| C355 | AMS 4215 | Bal | 1.0-1.5 | 4.5-5.5 | 0.10 | 0.40-0,60 | - | 0.20 | 0.10 max | 0.20 | - | - | - | - |

| A206 | AMS 4235 | Bal | 4.2-5.0 | .05max | 0.05 max | 0.20-0,35 | - | 0.10ma | 0.20-0,50 | 0.15-0.30 | - | - | 0.5 max | - |

| B206 | Bal | 4.2-5.0 | .05max | 0.05 max | 0.15-0,35 | - | 0.10 max | 0.20-0,50 | 0 10 | - | - | 0.5 max | - | |