OEM ea tloaelo ea koporo ea tšepe le likarolo tse ling tsa koporo tsa matsete li bapala karolo ea bohlokoa joalo ka ho jara lihlahla, likere, li-valve le 'mele oa pompo, lipeipi tsa metsi le tse ling.liindasteri tsa mochinitse hlokang ts'ebetso ea ho hanyetsa ho bola le ho apara ho hanyetsa.

Joaloka motsoako o sebelisoang ka ho fetisisa oa koporo, koporo e ka etsoa likarolo tse rarahaneng haholo tsa ho lahla, e leng se etsang hore e be tse loketseng mokhoa oa ho etsa lichelete. Ho feto-fetoha ha litšenyehelo kamehla ho ka etsa hore thepa ena e be bonolo haholo, e be e theko e boima haholo, haholo ha ho nahanoa ka machining a CNC le / kapa ho etsa joalo ka mokhoa oa ho etsa tlhahiso ea hau.likarolo tse lahliloeng. Leha ho le joalo, koporo e hloekileng hangata ha e tsoe. Brass ea ho lahla e na le lisebelisoa tse phahameng ho feta boronse, empa theko e tlase ho feta boronse.

Brass ke motsoako o entsoeng ka koporo le zinki. Brass e entsoeng ka koporo le zinki e bitsoa koporo e tloaelehileng. Haeba e le mefuta e fapaneng ea li-alloys e entsoeng ka likarolo tse fetang tse peli, e bitsoa koporo e khethehileng. Brass ke motsoako oa koporo o nang le zinki e le ntho e ka sehloohong. Ha lihlahisoa tsa zinki li ntse li eketseha, matla le polasetiki ea alloy li eketseha haholo, empa thepa ea mochine e tla fokotseha haholo ka mor'a ho feta 47%, kahoo zinki tsa koporo li ka tlaase ho 47%. Ho phaella ho zinki, koporo e entsoeng hangata e na le lisebelisoa tsa alloying tse kang silicon, manganese, aluminium le lead.

Seo re se Lahlelang ka Brass le Bronze

- • Maemo a China: H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2

- • USA Standard: C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100

- • Maemo a Europe: CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5

| Metal le Alloys e fumanehang bakeng sa Mekhoa e fapaneng ea ho Lahlela le ho Etsa

| ||

| MOEKETSI MOHAPI | TŠEBELETSO | |

| Ho Lahlela Lehlabathe | Ho Lahlela Lehlabathe le Letala | Grey Cast Iron, Ductile Cast Iron, Malleable Iron, Stainless Steel, Carbon Steel, Alloy Steel, Aluminium Alloy, Brass, joalo-joalo. |

| Resin Coated Sanding Casting | ||

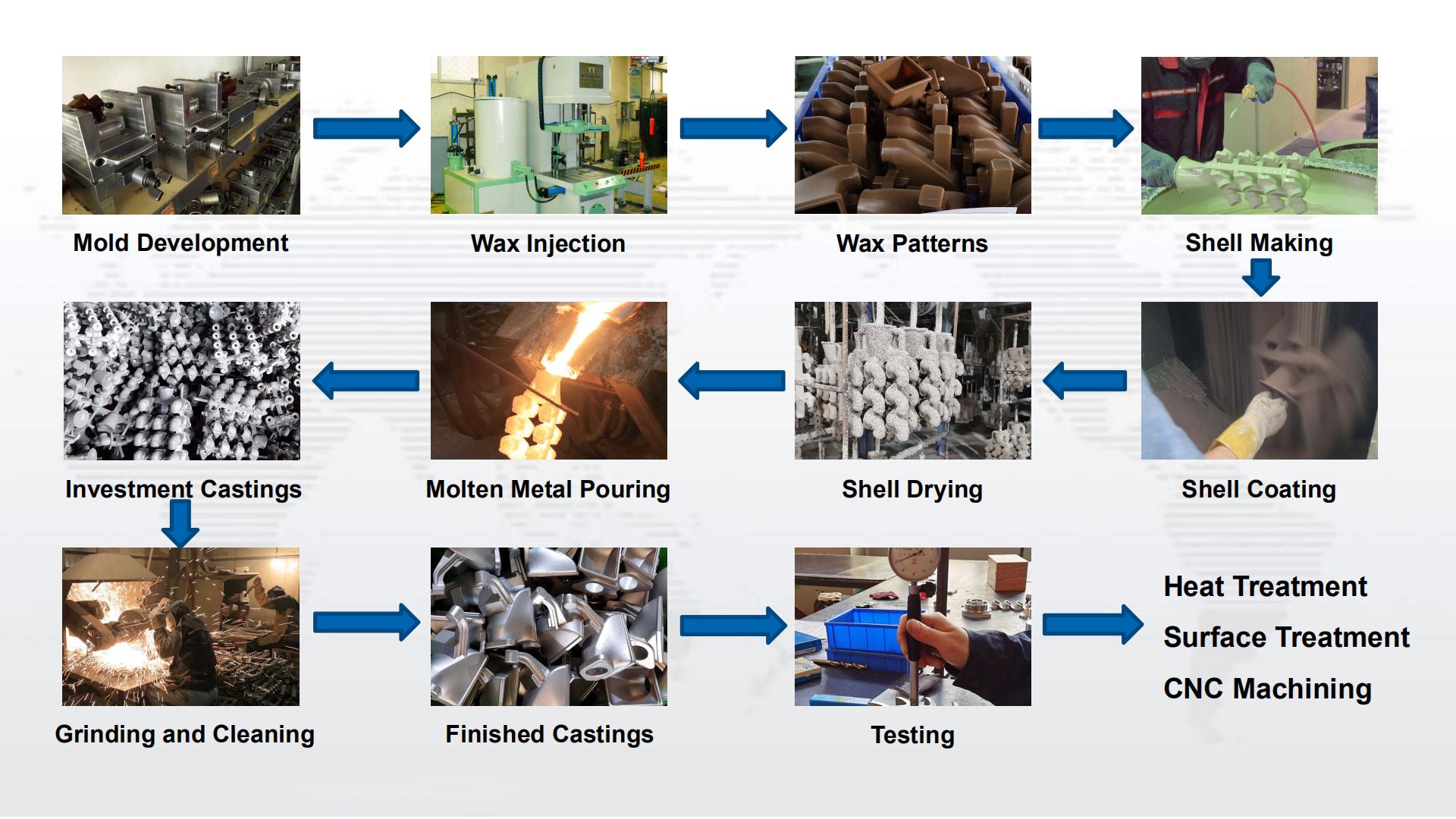

| Investment Casting (Lost Wax Casting) | Khalase ea metsi Investment Casting | Carbon Steel, Alloy Steel, Stainless Steel, Duplex Stainless Steel, Cast Iron, Brass, Aluminium le lisebelisoa tse ling. |

| Silica Sol Investment Casting | ||

| Ho Lahla Foam e Lahlehileng | Tšepe ea Ductile Cast / Grey Cast Iron | |

| ASTM 60-40-18 / 65-45-12 / 80-55-06 / 100-70-03 | ||

| Tšepe ea carbon, tšepe ea Hi-Mn, tšepe ea Hi-Cr | ||

| Austempering Ductile Iron (ADI) | ||

| Tšepe e sa Tletseng Mocheso / Ts'epe e Thibelang Mocheso | ||

| Vacuum Casting (V Process Casting) | Tšepe ea ductile GGG 40 ho ea ho GGG 80 / Grey Iron | |

| ASTM 60-40-18 / 65-45-12 / 80-55-06 / 100-70-03 | ||

| Tšepe ea carbon, tšepe ea Hi-Mn, tšepe ea Hi-Cr | ||

| Austempering ductile iron | ||

| Tšepe e thibelang mocheso / Roala tšepe e sa keneleng mocheso | ||

| Ho qapa | Open Forging | Stainless Steel, Carbon Steel, Alloy Steel, Brass, Aluminium |

| Shoa Forging | ||

| Roll Forging | ||

| Die Casting | High Pressure Die Casting | Aluminium, zinki, koporo |

| Tlas'a Khatello Die Casting | ||

| Gravity Pressure Die Casting | ||

| Litšebeletso tsa Kalafo ea Bokaholimo | Powder Coating, Anodization, Electrophotesis, Chrome Plating, Penta, Ho phatloha ha Lehlabathe, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, Geormet, Zintek, joalo-joalo. | |

| CNC Precision Machining Services | Lathing, Milling, Turning, Honing, Drilling, Boring, Tapping, Wire Electrode Cutting, Grinding ... joalo-joalo. | |

| Tlhahlobo le Taolo ea Boleng | Spectrum Analyzer, CMM, Hardness Tester, Tensile Strength Tester, Yild Strentgh Testor, Seling Pressure Tester, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester ... joalo-joalo. | |