Custom valve housing ea duplex stainless steel e hlahisoang ke investing casting from China casting foundry withmachining, phekolo ea mocheso, le litšebeletso tsa phekolo ea holim'a metsi.

RMC e bapalalikarolo tse nepahetseng tsa tšepee dulang e kgotsofatsa kapa e fetisang ditebello tsa bareki. Ho lahleheloa ke boka ba matsete a lichelete ho re lumella ho hlahisalihlahisoa tsa tšepe tse sa hloekange nyane joalo ka ligrama tse mashome le tse kholo joalo ka lik'hilograma tse mashome, ka mefuta e mengata ea li-alloys tse nang le tšepe le tse sa fereheng le ka ho nepahala ho ikhethang.

Ts'ebetso ea ho etsa matsete a boka e lahlehileng e hlahisa li-casting tse nepahetseng tsa sebopeho se haufi-ufi tseo hangata li hlokang mochini o eketsehileng kapa o sa hlokeng letho. Sephetho se hlahisoang le sona se betere ho feta se ka fihlellehang ka mekhoa e meng ea ho lahla kapa ea ho etsa. Matla le ho tšoarella ha likarolo tsa ho lahla li iketsetse tse loketseng bakeng sa lisebelisoa tse phahameng tse hanang ho apara tse hlokang limilione tsa li-cycle.

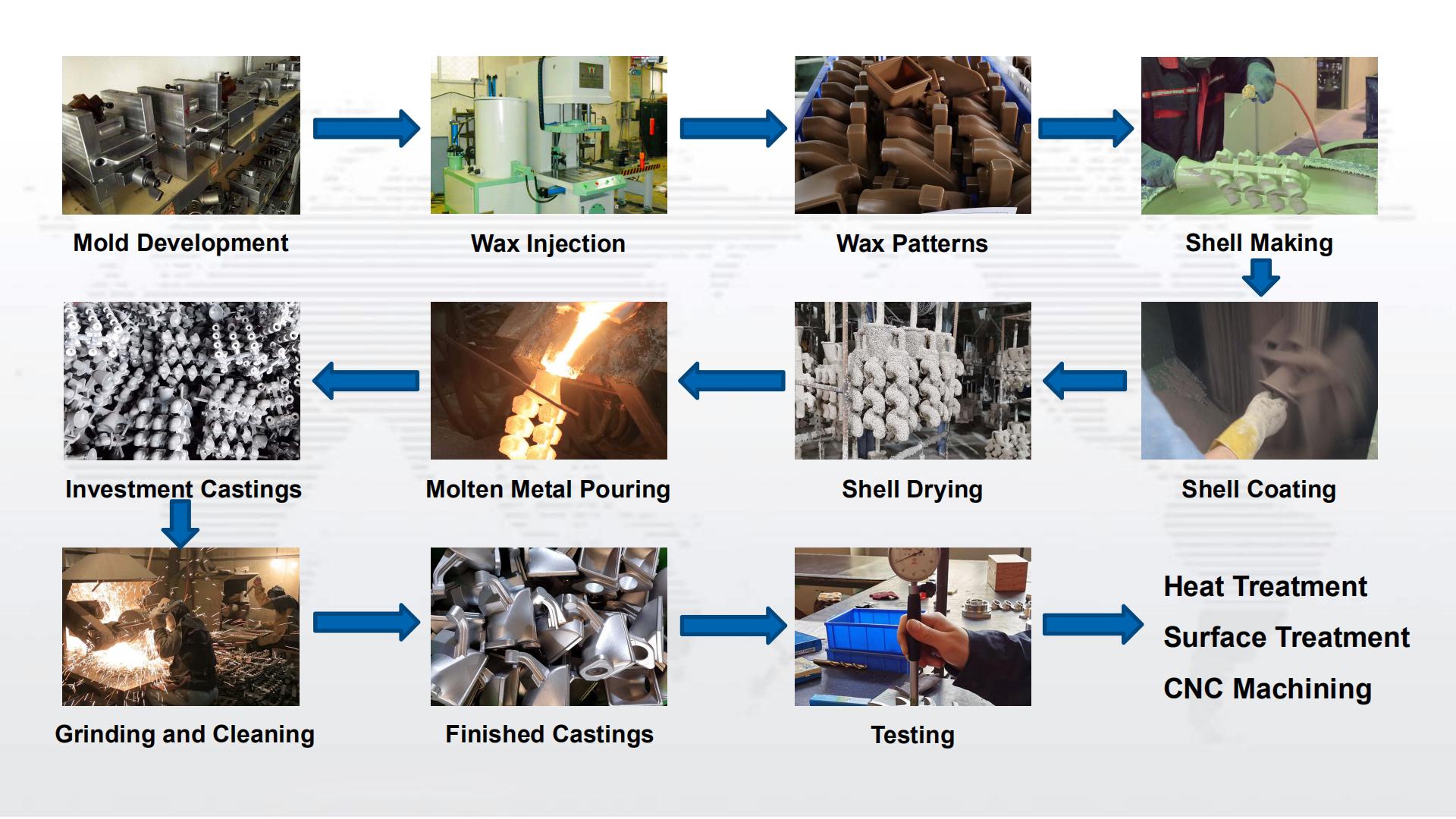

Mehato ea Ts'ebetso ea ho Lahlela Matsete:

Nakong ea ts'ebetso ea lichelete tsa lichelete, mohlala oa boka o koahetsoe ka thepa ea ceramic, eo, ha e thatafalitsoe, e amohelang geometry ea ka hare ea ho lahla ho lakatsehang. Maemong a mangata, likarolo tse ngata li kopantsoe hammoho bakeng sa ts'ebetso e phahameng ka ho hokela mekhoa ea boka e le 'ngoe ho thupa e bohareng ea boka e bitsoang sprue. Boka bo qhibilihisoa ka ntle ho mohlala - ke kahoo hape bo tsejoang e le mokhoa o lahlehileng oa boka - 'me tšepe e qhibilihisitsoeng e tšeloa ka mokoting. Ha tšepe e tiisa, hlobo ea ceramic e sisinyeha, e siea sebopeho se haufi sa marang-rang se lakatsehang, se lateloa ke ho qeta, ho hlahloba le ho paka.

Duplex Stainless Steel (DSS) e bua ka tšepe e sa hloekang e nang le ferrite le austenite e 'ngoe le e' ngoe e etsang karolo ea 50%. Ka kakaretso, litaba tsa mekhahlelo e fokolang li hloka bonyane 30%. Tabeng ea Cr e tlaase, litaba tsa Cr ke 18% ho 28%, 'me Ni content ke 3% ho 10%. Litšepe tse ling tsa duplex li boetse li na le likarolo tsa alloying tse kang Mo, Cu, Nb, Ti, le N.

Karolo e fumanehang ea tšepe e sa hloekang ea duplex ho RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890, 08 A9A 3A 890, 8 A9A 3A 890, 8 A9 A90 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS e na le litšobotsi tsa tšepe e sa hloekang ea austenitic le ferritic. Ha e bapisoa le ferrite, e na le polasetiki e phahameng le ductility, ha e na mocheso oa mocheso oa kamore, 'me e ntlafalitse haholo ho hanyetsa ho bola ha intergranular le ts'ebetso ea welding, ha e ntse e boloka brittleness, conductivity e phahameng ea mocheso, le superplasticity e le tšepe e sa hloekang ea ferrite. Ha e bapisoa le tšepe e sa hloekang ea austenitic, DSS e na le matla a phahameng 'me e ntlafalitse haholo ho hanyetsa corrosion ea intergranular le chloride stress corrosion. Tšepe e sa hloekang ea Duplex e na le khanyetso e ntle ea pitting corrosion hape ke tšepe e bolokang nickel.

| Kereiti e Tšoanang ea Stainless Steel | |||||||

| LIHLOPHA | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic le Ferritic Stainless Steel | 420 C | 1,4034 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Kr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Kr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 KAROLO 13 | 405 S 17 | - | F.3111 | X6 KAROLO 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Kr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Kr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Kr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Kr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Stainless Steel | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Steel | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

▶ Litšepe tse Ferrous le tse se nang ferrous bakeng saInvestment Casting, Mokhoa o Lahlehileng oa ho Lahlela boka:

• Tšepe e Hlooho: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Iron ea Ductile kapa Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Lisebelisoa tsa tšepe: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo... joalo-joalo ka kopo.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 le sehlopha se seng sa tšepe e sa hloekang.

• Koporo, Koporo e Khubelu, Bronze kapa tse ling tsa tšepe tse entsoeng ka koporo: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Lisebelisoa tse ling ho ea ka litlhoko tsa hau tse ikhethang kapa ho latela maemo a ASTM, SAE, AISI, ACI, DIN, EN, ISO, le GB

▶ Bokhoni ba hoInvestment Casting Foundry

• Boholo ba Boholo: 1,000 mm × 800 mm × 500 mm

• Boima ba Boima: 0,5 kg - 100 kg

• Bokhoni ba Selemo: Lithane tse 2,000

• Lisebelisoa tsa Bond bakeng sa Kaho ea Shell: Silica Sol, Glass ea Metsi le metsoako ea tsona.

| Litšebeletso | Tlhaloso |

| Litšebeletso tsa Kalafo ea Bokaholimo | Powder Coating, Anodization, Electrophotesis, Chrome Plating, Penta, Ho phatloha ha Lehlabathe, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, Geormet, Zintek, joalo-joalo. |

| CNC Precision Machining Services | Lathing, Milling, Turning, Honing, Drilling, Boring, Tapping, Wire Electrode Cutting, Grinding ... joalo-joalo. |

| Tlhahlobo le Taolo ea Boleng | Spectrum Analyzer, CMM, Hardness Tester, Tensile Strength Tester, Yild Strentgh Testor, Seling Pressure Tester, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester ... joalo-joalo. |