Lihlahisoa tsa tšepe tse bohlooho kamokhoa oa ho lahla hlobo ea lehlabathele mochini oa CNC.

Grey cast iron e bitsoa ka 'mala o moputsoa oa ho robeha ha eona. The grey cast iron e sebelisoa bakeng sa matlo moo ho satalla ha motsoako ho leng bohlokoa ho feta matla a eona a thata, joalo ka li-cylinder tsa enjene e tukang ka hare, matlo a pompo, 'mele ea li-valve, mabokose a motlakase, boima ba li-counter le li-castings tse khabisitsoeng. Matla a phahameng a mocheso a Grey cast iron le matla a khethehileng a hlooho hangata a sebelisoa hampe ho etsa li-cookware tsa tšepe le li-rotor tsa disc.

Sebopeho se tloaelehileng sa lik'hemik'hale ho fumana microstructure ea graphite ke 2.5 ho 4.0% carbon le 1 ho 3% silicon ka boima ba 'mele. Graphite e ka nka 6 ho isa ho 10% ea molumo oa tšepe e bohlooho. Silicon ke ea bohlokoa ho etsa tšepe e bohlooho ho fapana le tšepe e tšoeu ea tšepe, hobane silicon ke karolo ea graphite e tsitsitseng ka tšepe e entsoeng ka tšepe, e bolelang hore e thusa motsoako ho hlahisa graphite ho e-na le li-carbides tsa tšepe; ka 3% silicon hoo e ka bang ha ho na carbon e tšoaroang ka lik'hemik'hale hammoho le tšepe.

graphite e nka sebōpeho sa letlapa la mahlakore a mararo. Ka litekanyo tse peli, ha sebaka se bentšitsoeng se tla hlaha ka tlas'a microscope, li-flakes tsa graphite li hlaha e le mela e metle. Malebela a li-flakes a sebetsa joalo ka li-notch tse seng li le teng; ka hona, e brittle. Ho ba teng ha graphite flakes ho etsa hore Grey Iron e khonehe habonolo kaha e atisa ho petsoha habonolo ho pholletsa le li-graphite flakes. Grey iron e boetse e na le matla a matle haholo a ho phopholetsa, ka hona e sebelisoa haholo joalo ka motheo oa lisebelisoa tsa mochini.

Gray Cast Iron Mechanical Properties | |||||||

| Ntho ho latela DIN EN 1561 | Lekanya | Yuniti | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Matla a tšepe | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Matla a Puno | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Elongation Matla | A | % | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 |

| Matla a Khatellang | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Matla a Khatellang | σd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Flexural Matla | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Ho Shear Khatello | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Li-module tsa elasticity | E | GPA | 78-103 | 88-113 | 103 - 118 | 108 - 137 | 123 - 143 |

| Nomoro ea Poisson | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Ho thatafala ha Brinell | HB | 160-190 | 180 - 220 | 190-230 | 200 - 240 | 210 - 250 | |

| Ductility | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Ho fetoha ha tsitsipano le khatello | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Matla a Qhoba | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Botenya | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Ho lahla lehlabathe ho sebelisa lehlabathe le letala (lehlabathe le mongobo) kapa lehlabathe le omeletseng ho etsa mekhoa ea ho bopa. Ho lahla lehlabathe le letala ke mokhoa oa khale oa ho lahla o sebelisitsoeng historing. Ha ho etsoa hlobo, lipaterone tse entsoeng ka lehong kapa tšepe li lokela ho hlahisoa e le hore li thehe sekoti se sekoti. Ka mor'a moo, tšepe e qhibilihisitsoeng e tšela ka mokoting ho etsa li-castings ka mor'a ho pholile le ho tiisa. Ho lahla lehlabathe ho theko e tlase ho feta lits'ebetso tse ling bakeng sa nts'etsopele ea hlobo le karolo ea ho lahlela yuniti. Ho lahla lehlabathe, kamehla ho bolela ho lahla lehlabathe le letala (haeba ho se na tlhaloso e khethehileng). Leha ho le joalo, matsatsing ana, mekhoa e meng ea ho lahla le eona e sebelisa lehlabathe ho etsa hlobo. Ba na le mabitso a bona, joalo kaho lahla hlobo, furan resin e koahetsoeng ka lehlabathe (ha ho mofuta oa ho baka),foam e lahlehilengle vacuum casting.

Matla a ho Lahlela Lehlabathe ho RMC Foundry | ||

| Tlhaloso | Ho Bopa ka Bukana | Ho bopa ka Mechini e Iketsetsang |

| Boholo ba Castings | 1,500 limilimithara × 1000 limilimithara × 500 limilimithara | 1,000 limilimithara × 800 limilimithara × 500 limilimithara |

| Range Weight Range | 0,5 lik'hilograma - 1,000 lik'hilograma | 0.5 lik'hilograma - 500 lik'hilograma |

| Bokhoni ba Selemo | Lithane tse 5,000 - lithane tse 6,000 | Lithane tse 8,000 - lithane tse 10,000 |

| Mamello ea ho Lahlela | Ka Kopo kapa Tekanyetso (ISO8062-2013 kapa GB/T 6414-1999) | |

| Lisebelisoa tsa ho Bopa | Lehlabathe le Letala, Lehlabathe le koahetsoeng ke Resin | |

| Ho Lahlela Metal & Alloys | Grey Iron, Ductile Iron, Cast Steel, Stainless Steel, Al Alloys, Brass, Bronze ... joalo-joalo. | |

Melemo ea Sand Casting:

- ✔ Theko e tlase ka lebaka la thepa ea eona ea hlobo e theko e tlaase le e ka sebelisoang hape le lisebelisoa tse bonolo tsa tlhahiso.

- ✔ Mefuta e mengata ea boima ba yuniti ho tloha ho 0.10 kg ho isa ho 500 kgs kapa ho feta.

- ✔ Sebopeho se fapaneng ho tloha ho mofuta o bonolo ho isa ho o rarahaneng.

- ✔ E loketse litlhoko tsa tlhahiso ea bongata bo fapaneng.

Mamello eo Li-Castings tsa Lehlabathe li li Finyellang:

Mamello ea ho lahla e arotsoe ka Dimensional Casting Tolerances (DCT) le Geometrical Casting Tolerances (GCT). Setsi sa rona se ka thabela ho bua le uena haeba u na le kopo e khethehileng mabapi le mamello e hlokahalang. Mona ho tse latelang ke boemo ba ho mamellana ka kakaretso boo re ka bo fihlelang ka ho lahla lehlabathe le letala, ho lahla hlobo ea likhetla le lehlabathe le sa bakeng la furan resin:

- ✔ DCT Kereiti ka Green Sand Casting: CTG10 ~ CTG13

- ✔ DCT Kereiti ka Shell Mold Casting kapa Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ Kereiti ea GCT ka Green Sand Casting: CTG6 ~ CTG8

- ✔ Kereiti ea GCT ka Shell Mold Casting kapa Furan Resin Sand Casting: CTG4 ~ CTG7

Metal & Alloys Grade bakeng sa Mekhoa ea ho Lahlela Lehlabathe | |

| Metal & Alloys | Sehlopha se Tsebahalang |

| Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ts'epi ea Ductile (Nodualar) | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Tšepe ea Carbon | C20, C25, C30, C45 |

| Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Ts'epe e sa beng le mabali | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Pula e thatafatsa Stainless Steel, Duplex Stainless Steel |

| Lisebelisoa tsa Aluminium | ASTM A356, ASTM A413, ASTM A360 |

| Lisebelisoa tsa koporo / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, le GB | |

-

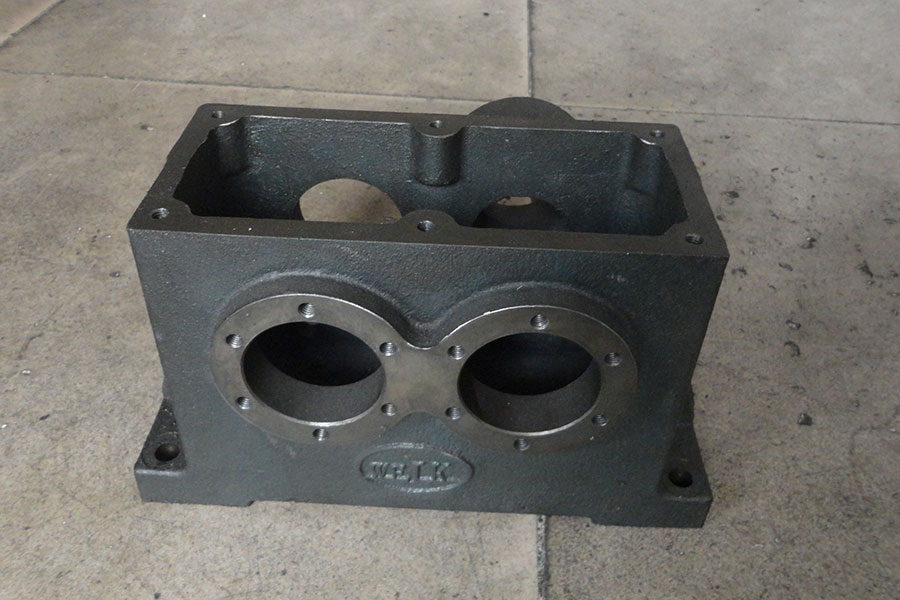

Sehlahisoa sa Grey Cast Iron Sand

-

Sehlahisoa sa Grey Cast Iron Shell

-

OEM Grey Casting ea tšepe

-

Alloy Steel Resin Coated Sanding Crankshaft

-

Alloy Steel Sand Castings

-

Alloy Steel Truck Parts by Sand Casting le CNC...

-

Khampani ea ho Lahlela Lehlabathe la Carbon

-

Cast Steel Sanding

-

Aluminium Alloy Sand Casting