Industrial electrocoating ke ho pharaletseng sebelisoa holim'a phekolo bakeng sa ho sireletsalitšepe tsa tšepele lihlahisoa tsa machining tsa CNC tse tsoang ho corrosion tse nang le pheletso e ntle. Bareki ba bangata ba botsa lipotso mabapi le phekolo ea holim'a tšepe ea tšepe lelikarolo tse entsoeng ka nepo. Sehlooho sena se tla lebisa tlhokomelo ho mokhoa oa ho roala ka electrophoretic. Ke tšepa hore e tla ba molemo ho balekane bohle.

Electrocoating ke mokhoa oa ho roala oo likaroloana tse kang li-pigments le li-resin tse emisitsoeng ka tharollo ea electrophoretic li lebisitsoe ho falla le ho kenya holim'a e 'ngoe ea li-electrode ka ho sebelisa tšimo ea motlakase e ka ntle. Molao-motheo oa ho roala ka electrophoretic o qapiloe qetellong ea lilemo tsa bo-1930, empa theknoloji ena e ile ea ntlafatsoa 'me ea fumanoa ts'ebetsong ea indasteri ka mor'a 1963. Ho roala ha electrophoretic ke mokhoa o sebetsang ka ho fetisisa oa kaho bakeng sa ho roala metsi. Ho roala ha electrophoretic ho na le litšobotsi tsa ho qhibiliha ha metsi, ho se chefo, le ho laola habonolo ka mokhoa o itekanetseng. Hobane e loketse bakeng sa kalafo ea holim'a li-workpieces tsa conductive (metal castings, likarolo tsa mochini, forgings, likarolo tsa tšepe le likarolo tsa welding, joalo-joalo), ts'ebetso ea ho roala ka electrophoretic e se e sebelisoa ka potlako liindastering tse kang likoloi, thepa ea moaho, hardware. , le lisebelisoa tsa lapeng.

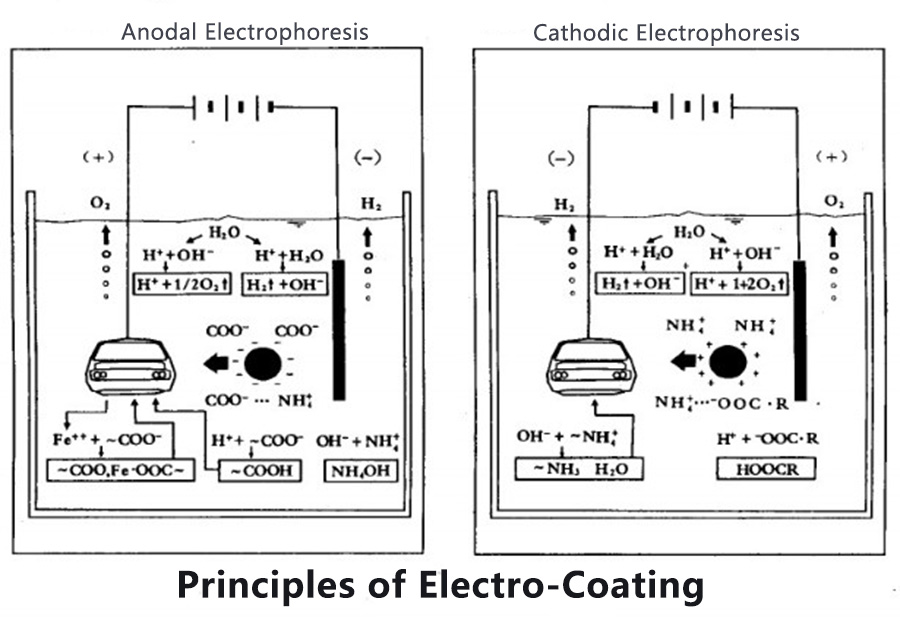

Melao-motheo

Resin e ka har'a cathodic electrophoretic coating e na le lihlopha tsa motheo, tse etsang letsoai ka mor'a ho fokotsa acid le ho qhibiliha ka metsing. Ka mor'a hore ho sebelisoe hona joale ka ho toba, li-ion tsa acid tse feteletseng li fallela ho anode, 'me li-ion tsa resin le likaroloana tsa pigment tse phuthetsoeng ke tsona li fallela cathode ka litefiso tse ntle' me li kenngoa ka har'a cathode. Ena ke molao-motheo oa ho roala ka electrophoretic (eo hangata e tsejoang e le plating). Ho roala ha electrophoresis ke mokhoa o rarahaneng haholo oa electrochemical reaction, bonyane liphello tse 'nè tsa electrophoresis, electrodeposition, electrolysis, le electroosmosis li etsahala ka nako e le' ngoe.

Electrophoresis

Ka mor'a hore anode le cathode ka tharollo ea colloidal li sebelisoe, likaroloana tsa colloidal li fallela lehlakoreng la cathode (kapa anode) tlas'a ketso ea tšimo ea motlakase, e bitsoang electrophoresis. Ntho e ka har'a motsoako oa colloidal ha e boemong ba limolek'hule le li-ion, empa solute e hasaneng mokelikeli. Ntho e kholo 'me e ke ke ea e-ba sebakeng se qhalakaneng.

Electrodeposition

Ketsahalo ea pula e tiileng e tsoang ho mokelikeli e bitsoa agglomeration (agglomeration, deposition), eo hangata e hlahisoang ha ho pholile kapa ho tsitsisa tharollo, 'me ho roala ha electrophoretic ho itšetlehile ka motlakase. Ka cathodic electrophoretic coating, positive charged particles aggregate on the cathode, le negative charges particles (ie ions) aggregate on anode. Ha likaroloana tse ntle tsa colloidal (resin le pigment) li fihla ho cathode (substrate) Ka mor'a hore sebaka se holim'a metsi (lesela le leholo la alkaline), li-electrone li fumanoa 'me li itšoara ka li-ion tsa hydroxide ho fetoha lintho tse sa tsitsang metsi, tse behiloeng holim'a cathode. pentiloe workpiece).

Electrolysis

Ka tharollo e nang le conductivity ea ionic, anode le cathode li kopantsoe le hona joale ka ho toba, li-anions li khahloa ke anode, 'me li-cation li khahloa ke cathode,' me ho etsahala lik'hemik'hale. Anode e hlahisa ho qhibiliha ha tšepe le electrolytic oxidation ho hlahisa oksijene, chlorine, joalo-joalo Anode ke electrode e ka hlahisang karabelo ea oxidation. The tšepe e precipitated ka cathode le H+ e electrolytically fokotswa ho hydrogen.

Electroosmosis

Ka mor'a hore lipheletsong tse peli (cathode le anode) tsa tharollo tse nang le likhahla tse fapaneng tse arohaneng le lera la semipermeable li matlafalitsoe, ketsahalo ea hore tharollo e tlaase ea concentration e fallela lehlakoreng le phahameng-concentration e bitsoa electroosmosis. Filimi ea ho roala e sa tsoa kenngoa holim'a ntho e koahetsoeng ke filimi e nang le semi-permeable. Tlas'a ketso e tsoelang pele ea tšimo ea motlakase, metsi a nang le dialysis ea filimi e tlotsang ka ntle ho filimi 'me a fallela bateng ho senya filimi. Sena se bitsoa electroosmosis. Electroosmosis e fetola filimi ea ho roala ka hydrophilic hore e be filimi ea ho roala ka hydrophobic, 'me ho felloa ke metsi ho etsa hore filimi ea ho roala e be e teteaneng. Pente e metsi ka mor'a ho sesa ka pente e ntle ea electro-osmosis electrophoretic e ka ama 'me ea se ke ea khomarela. U ka hlatsoa mokelikeli oa ho hlapa o khomarela filimi ea pente e metsi ka metsi.

Litšobotsi tsa Electrocoating

Filimi ea pente ea Electrophoretic e na le melemo ea botlalo, ho tšoana, ho bata le ho roala boreleli. Ho thatafala, ho khomarela, ho hanyetsa kutu, ts'ebetso ea ts'ebetso, le ho phunyeletsa ha filimi ea pente ea electrophoretic e molemo haholo ho feta mekhoa e meng ea ho roala.

(1) Pente e qhibilihang ka metsi e sebelisoa, metsi a sebelisoa e le mokhoa oa ho qhibiliha, o bolokang lihlahisoa tse ngata tsa tlhaho, o fokotsa haholo tšilafalo ea moea le likotsi tsa tikoloho, o bolokehile ebile o hloekile, 'me o qoba kotsi e patehileng ea mollo;

(2) Bokhoni ba ho penta bo phahame, tahlehelo ea pente e nyane, mme sekhahla sa tšebeliso ea pente se ka fihla ho 90% ho isa ho 95%;

(3) Botenya ba filimi ea ho roala bo lekana, sekhomaretsi se matla, 'me boleng ba ho roala bo botle. Karolo e 'ngoe le e' ngoe ea lisebelisoa tsa mosebetsi, tse kang lera le ka hare, li-depressions, welds, joalo-joalo, li ka fumana filimi ea ho roala junifomo le e boreleli, e rarollang bothata ba mekhoa e meng ea ho roala bakeng sa li-workpieces tse nang le sebōpeho se rarahaneng. Bothata ba ho penta;

(4) Ts'ebetso ea tlhahiso e phahame, 'me mohaho o ka khona ho hlahisa tlhahiso e ikemetseng le e tsoelang pele, e ntlafatsang haholo katleho ea mosebetsi;

(5) Thepa e rarahane, litšenyehelo tsa matsete li holimo, tšebeliso ea matla e kholo, mocheso o hlokahalang bakeng sa ho omisa le ho phekola o phahame, tsamaiso ea pente le ho penta e rarahane, maemo a kaho a thata, 'me ho hlokahala ho hloekisa metsi a litšila. ;

(6) Ho ka sebelisoa pente e qhibilihang ka metsing feela, 'me 'mala o ke ke oa fetoloa nakong ea ho roala. Ho tsitsa ha pente ha ho bonolo ho laola ka mor'a ho boloka nako e telele.

(7) Thepa ea ho roala ka electrophoretic e rarahane 'me litaba tsa theknoloji li phahame, tse loketseng ho hlahisa mebala e tsitsitseng.

Meeli ea Electrocoating

(1) E loketse feela ho roala li-primer tsa li-conductive substrates tse kang likarolo tsa mochine tsa tšepe tse nang le tšepe le litšepe tse se nang ferrous. Lintho tse se nang conductive tse kang lehong, polasetiki, lesela, joalo-joalo li ke ke tsa koaheloa ka mokhoa ona.

(2) Ts'ebetso ea ho roala ka electrophoretic ha e tšoanelehe bakeng sa lintho tse koahetsoeng tse entsoeng ka litšepe tse ngata, haeba litšobotsi tsa electrophoresis li fapane.

(3) Ts'ebetso ea ho roala ka electrophoretic e ke ke ea sebelisoa bakeng sa lintho tse koahetsoeng tse ke keng tsa mamella mocheso o phahameng.

(4) Ho roala ha electrophoretic ha hoa lokela ho roala ka litlhoko tse fokolang ka 'mala. Ho roala ha electrophoretic ka mebala e fapaneng ho hloka ho penta ka li-grooves tse fapaneng.

(5) Ho roala ka electrophoretic ha ho khothalletsoe bakeng sa tlhahiso ea li-batch tse nyenyane (nako ea ho nchafatsa ea ho hlapa e feta likhoeli tse 6), hobane lebelo la ho nchafatsa bateng le lieha haholo, resin e ka bateng e ea tsofala le lintho tse hlapollang lia fetoha. haholo. Bate ha e tsitsa.

Mehato ea Electrocoating

(1) Bakeng sa ho roala ka electrophoretic ka holim'a tšepe e tloaelehileng, mokhoa oa ho phalla ke: ho hloekisa pele → ho hloekisoa → ho hlatsoa metsi → ho hlatsoa metsi → ho tlosa mafome → ho hlatsoa metsi → ho se nke lehlakore → ho hlatsoa metsi → phosphating → ho hlatsoa metsi → passivation → electrophoretic coating → tank top Cleaning → ho hlatsoa metsi ka matla → ho omisa → ntle le marang-rang.

(2) Substrate le pretreatment ea ntho e koahetsoeng e na le tšusumetso e kholo filiming ea electrophoretic. Lisebelisoa tsa tšepe hangata li senngoa ke ho phatloha ha lehlabathe kapa ho thunngoa, khoele ea k'hothone e sebelisoa ho tlosa lerōle le phaphametseng holim'a mosebetsi, 'me sandpaper e sebelisetsoa ho tlosa lithunya tse setseng tsa tšepe le litšila tse ling holim'a metsi. Sebaka sa tšepe se tšoaroa ka ho tlosa le ho tlosa mafome. Ha litlhoko tsa bokaholimo li phahame haholo, ho hlokahala kalafo ea phosphating le passivation. Lisebelisoa tsa tšepe tse entsoeng ka tšepe li tlameha ho ba phosphated pele ho anodic electrophoresis, ho seng joalo, ho hanyetsa ha kutu ea filimi ea pente ho tla fokola. Ka phekolo ea phosphating, filimi ea zinki ea phosphating ea letsoai e khethoa ka kakaretso, e nang le botenya bo ka bang 1 ho 2 μm, 'me filimi ea phosphate e hlokeha ho ba le likristale tse ntle le tse tšoanang.

(3) Tsamaisong ea ho hloekisa, mokhoa o ka sehloohong oa ho hloekisa o amoheloa ka kakaretso, 'me sefa ke sebopeho sa mokotla oa mesh. Pente ea electrophoretic e isoa ho sefa ka pompo e emeng bakeng sa ho sefa. Ha ho nahanoa ka potoloho e felletseng ea phetoho le boleng ba filimi ea pente, mokotla oa filthara o nang le pore ea 50μm ke ona o motle ka ho fetisisa. E ke ke ea finyella litlhoko tsa boleng ba filimi ea pente feela, empa hape e rarolla bothata ba ho koala mokotla oa filthara.

(4) Boholo ba tsamaiso ea potoloho ea ho roala ha electrophoretic e ama ka ho toba botsitso ba ho hlapa le boleng ba filimi ea pente. Ho eketsa molumo oa potoloho ho fokotsa pula le li-bubble tsa mokelikeli oa ho hlapa; leha ho le joalo, botsofali ba mokelikeli oa ho hlapa bo potlakisa, tšebeliso ea matla e eketseha, 'me botsitso ba mokelikeli oa ho hlapa bo mpefala. Ho loketse ho laola linako tsa potoloho ea metsi a tanka ho 6-8 linako / h, e sa tiiseng feela boleng ba filimi ea pente, empa hape e tiisa ts'ebetso e tsitsitseng ea metsi a tanka.

(5) Ha nako ea tlhahiso e ntse e eketseha, tšitiso ea anode diaphragm e tla eketseha mme matla a sebetsang a sebetsang a tla fokotseha. Ka hona, tlhahisong, motlakase o sebetsang oa phepelo ea motlakase o lokela ho eketseha butle-butle ho latela tahlehelo ea motlakase ho lefella ho theoha ha voltage ea anode diaphragm.

(6) Sistimi ea ultrafiltration e laola khatello ea li-ion tse sa hloekang tse tlisoang ke sesebelisoa ho netefatsa boleng ba ho roala. Ts'ebetsong ea tsamaiso ena, hoa lokela ho hlokomeloa hore hang ha tsamaiso e ntse e sebetsa, e lokela ho sebetsa e sa khaotse 'me e thibetsoe ka thata ho matha ka nakoana ho thibela lera la ultrafiltration hore le se ke la omella. Resin e omisitsoeng le pigment li khomarela lera la ultrafiltration 'me li ke ke tsa hloekisoa ka ho feletseng, tse tla ama ka ho teba ho phunyeletsa ha metsi le bophelo ba tšebeletso ea lera la ultrafiltration. Sekhahla sa tlhahiso ea metsi ea lera la ultrafiltration se bontša mokhoa o theohang ka nako ea ho sebetsa. E lokela ho hloekisoa hanngoe bakeng sa matsatsi a 30-40 a mosebetsi o tsoelang pele ho netefatsa hore metsi a ultrafiltration a hlokehang bakeng sa leaching ea ultrafiltration le ho hlatsoa.

(7) Mokhoa oa ho roala ka electrophoretic o loketse bakeng sa ts'ebetso ea tlhahiso ea palo e kholo ea melapo ea kopano. Phetoho ea ntlafatso ea bate ea electrophoresis e lokela ho ba ka hare ho likhoeli tse 3. Tsamaiso ea saense ea ho hlapa ke ea bohlokoa haholo. Mefuta e fapa-fapaneng ea ho hlapa e lekoa khafetsa, 'me ho hlapa ho fetoloa le ho nkeloa sebaka ho latela liphetho tsa liteko. Ka kakaretso, litekanyetso tsa tharollo ea ho hlapa li lekanngoa ka makhetlo a latelang: pH value, solid content and conductivity of electrophoresis solution, ultrafiltration solution le ultrafiltration clean solution, anion (anode) polar solution, circulating lotion, le deionization clean solution hang. letsatsi; Base ratio, organic solvent content, le laboratori e nyane ea liteko tsa tanka habeli ka beke.

(8) Bakeng sa tsamaiso ea boleng ba filimi ea pente, ho ts'oana le botenya ba filimi ea pente e lokela ho hlahlojoa khafetsa, 'me ponahalo ha ea lokela ho ba le likoti, ho sagging, lekhapetla la lamunu, wrinkles, joalo-joalo Kamehla hlahloba' mele le lik'hemik'hale. lipontšo tse kang ho khomarela le ho hanyetsa ha kutu ea filimi ea ho roala. Nako ea tlhahlobo e tsamaellana le litekanyetso tsa tlhahlobo ea moetsi, 'me ka kakaretso sehlopha ka seng se hloka ho hlahlojoa.

Phekolo ea Bokaholimo Pele ho Electrophoresis

Kalafo ea holim'a workpiece pele ho roala ke karolo ea bohlokoa ea ho roala ha electrophoretic, haholo-holo ho kenyelletsa ho senya, ho tlosoa ha mafome, ho lokisa holim'a metsi, phosphating le mekhoa e meng. Boleng ba phekolo ea eona ha bo ame feela ponahalo ea filimi, e fokotsa ts'ebetso e khahlanong le kutu, empa hape e senya botsitso ba tharollo ea pente. Ka hona, bakeng sa holim'a workpiece pele ho penta, ho hlokahala hore ho se be le litšila tsa oli, matšoao a mafome, ho se na lik'hemik'hale tsa pele le phosphating sedimentation, joalo-joalo, 'me filimi ea phosphating e na le likristale tse teteaneng le tse tšoanang. Mabapi le mekhoa e fapaneng ea kalafo pele ho kalafo, re ke ke ra buisana ka eona ka bomong, empa re tla fana ka lintlha tse 'maloa feela tsa tlhokomelo:

1) Haeba ho fokotseha le mafome li sa hloeka, li ke ke tsa ama feela ho thehoa ha filimi ea phosphating, empa hape e ama matla a tlamahano, ts'ebetso ea mokhabiso le ho hanyetsa ha kutu ea ho roala. Filimi ea pente e na le tšekamelo ea ho fokotseha le li-pinholes.

2) Phosphating: Sepheo ke ho ntlafatsa bokhoni ba ho khomarela le ho thibela ho bola ha filimi ea electrophoretic. Karolo ea eona ke e latelang:

(1) Ka lebaka la liphello tsa 'mele le lik'hemik'hale, ho khomarela filimi ea ho roala ka manyolo ho substrate hoa ntlafatsoa.

(2) Filimi ea phosphating e fetola bokaholimo ba tšepe ho tloha mokhanni o motle ho ea ho mokhanni ea futsanehileng, ka hona e thibela ho thehoa ha li-betri tse nyane holim'a tšepe, e thibelang ho bola ha lesela, le ho eketsa ho hanyetsa ha kutu le ho hanyetsa metsi. ho roala. Ho phaella moo, feela motheong oa ho theoha ka ho feletseng le ho fokotseha, filimi e khotsofatsang ea phosphating e ka thehoa holim'a sebaka se hloekileng, sa junifomo le se se nang mafura. Ho tloha ntlheng ena, filimi ea phosphating ka boeona ke mokhoa o hlakileng le o tšepahalang oa ho itlhahloba mabapi le phello ea ts'ebetso ea pele ho kalafo.

3) Ho hlatsoa: Boleng ba ho hlatsoa boemong bo bong le bo bong ba pele ho nako bo tla ba le tšusumetso e kholo ho boleng ba filimi eohle ea pele le ea pente. Ho hloekisoa ha metsi ho qetela pele ho penta, etsa bonnete ba hore conductivity e rothang ea ntho e koahetsoeng ha e kholo ho feta 30μs / cm. Ho hloekisa ha hoa hloeka, joalo ka workpiece:

(1) Residual acid, phosphating chemical liquid, flocculation ea resin ka mokelikeli oa pente, le ho senyeha ha botsitso;

(2) Lintho tse setseng tse tsoang linaheng tse ling (litsila tsa oli, lerōle), likoti tsa shrinkage, likaroloana le liphoso tse ling filiming ea pente;

(3) Li-electrolyte tse setseng le matsoai li lebisa ho mpeng ha karabelo ea electrolysis le ho hlahisa li-pinholes le mafu a mang.

Nako ea poso: Apr-17-2021