China OEM tloaelo spheroidal graphite lahla tšepe khetla hlobo lahla lihlahisoa tsa litšebeletso tsaMechine ea CNC, phekolo ea mocheso le phekolo ea holim'a metsi.

Shell molding castingprocess e boetse e bitsoa pre-coated resin sand casting process, hot shell molding castings kapa core casting process. Ntho e ka sehloohong ea ho bōptjoa ke lehlabathe la phenolic resin le koahetsoeng esale pele, le theko e boima ho feta lehlabathe le letala le lehlabathe la resin ea furan. Ho feta moo, lehlabathe lena le ke ke la sebelisoa hape.

Mokhoa oa ho lahla lehlabathe la Furan resin (mokhoa oa nobake) o sebelisa lehlabathe le koahetsoeng ka lehlabathe la furan ho etsa hlobo ea ho lahla. Ka mor'a ho kopanya lehlabathe la pele (kapa lehlabathe le tsosolositsoeng), metsi a furan resin le catalyst ea metsi ka mokhoa o ts'oanang, ebe o li tlatsa ka lebokoseng la mantlha (kapa lebokose la lehlabathe), ebe o le tiisa hore le thatafale ka har'a hlobo kapa hlobo ka lebokoseng la mantlha (kapa lehlabathe). box) ka mocheso oa kamore. Joale ho ile ha thehoa hlobo ea ho lahla kapa ho lahla, e bitsoang "self-harding batang-core box molding" (konokono), kapa mokhoa oa ho ithatafatsa (konokono).

Hobane hlobo e entsoe ka mocheso oa kamore 'me ha ho hlokahale hore e futhumale, ho lahla lehlabathe le ithatafatsang ho boetse ho bitsoa mokhoa oa ho lahla o sa bake. Mokhoa oa ho ithatafatsa o ka aroloa ka acid-catalyzed furan resin le phenolic resin sand self-harding method, urethane resin sand in self-harding method le phenolic monoester self-harding.

Joalo ka lehlabathe le ithatafatsang la lebokose le batang, lehlabathe la resin la furan ke lehlabathe la pele le sebelisoang haholo hona joale le sebelisoang haholo setsing sa Machaena. Palo ea resin e kentsoeng lehlabatheng le bōpiloeng hangata ke 0.7% ho isa ho 1.0%, 'me palo ea resin e kentsoeng lehlabatheng la mantlha hangata ke 0.9% ho isa ho 1.1%. Likahare tsa aldehyde ea mahala ho resin ea furan li ka tlase ho 0.3%, 'me lifeme tse ling li theohetse ka tlase ho 0.1%. Libakeng tse thehiloeng Chaena, lehlabathe le ithatafatsang la furan resin le fihlile boemong ba machaba ho sa tsotellehe ts'ebetso ea tlhahiso le boleng ba holim'a li-castings.

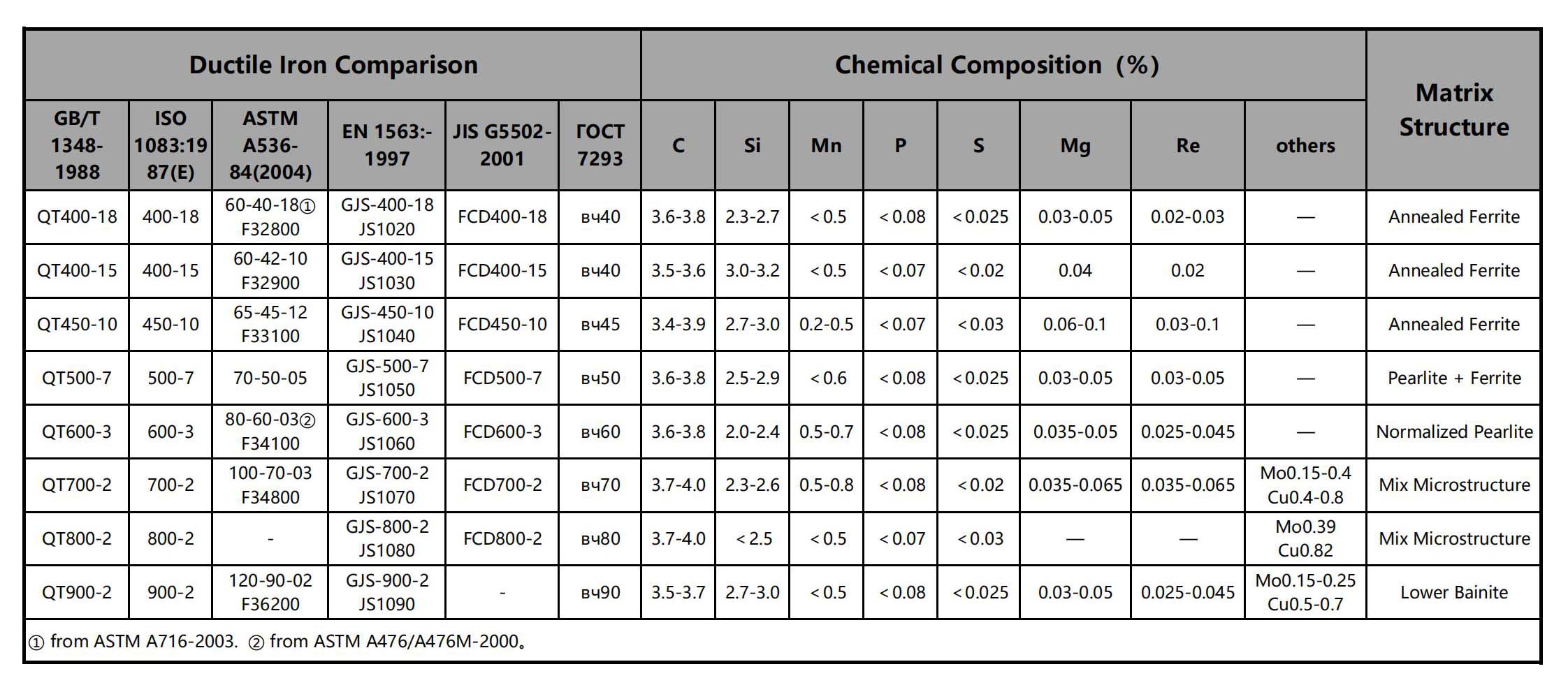

Ductile cast iron, eo hape e bitsoang nodular cast iron, spheriodal graphite cast iron kapa feela SG iron for short, emela sehlopha sa tšepe ea tšepe. Nodular cast iron e fumana nodular graphite ka phekolo ea spheroidization le inoculation, e leng ho ntlafatsa ka katleho thepa ea mochine oa tšepe ea tšepe, haholo-holo polasetiki le ho tiea, e le ho fumana matla a phahameng ho feta carbon steel.

Lisebelisoa tsa tšepe tsa ductile li na le ts'ebetso e ntle ea ho monya ho ts'oenyeha ho feta carbon steel, athe li-casting tsa carbon steel li na le cheseletso e ntle haholo. 'Me ho isa bohōleng bo itseng, li-ductile iorn castings li ka ba le litšoantšiso tse ling tsa ho roala le mafome. Kahoo ho lahla tšepe ea ductile ho ka sebelisoa bakeng sa matlo a pompo kapa lisebelisoa tsa phepelo ea metsi. Leha ho le joalo, re ntse re hloka ho etsa mehato ea ho li sireletsa hore li se ke tsa apara le ho rusa.

Tšepe ea ductile hase ntho e le 'ngoe empa ke karolo ea sehlopha sa lisebelisoa tse ka hlahisoang ho ba le mefuta e mengata ea thepa ka ho laola microstructure. Tšobotsi e tloaelehileng e hlalosang sehlopha sena sa lisebelisoa ke sebōpeho sa graphite. Ka litšepe tsa ductile, graphite e ka sebōpeho sa li-nodule ho e-na le li-flakes joalokaha e le ka tšepe e bohlooho. Sebopeho se hlabang sa li-flakes tsa graphite se etsa hore ho be le lintlha tsa khatello ea kelello ka har'a matrix ea tšepe le sebōpeho se chitja sa li-nodule tse fokolang haholo, kahoo li thibela ho thehoa ha mapetsong le ho fana ka ductility e ntlafetseng e fanang ka alloy lebitso la eona. Ka kakaretso, haeba tšepe ea ductile e ka finyella litlhoko tsa hau, tšepe ea ductile e ka ba khetho ea hau ea pele, ho e-na le tšepe ea carbon bakeng sa li-castings tsa hau.

| Resin Coated Lehlabathe Lahlela Metal le Alloys | |

| Metal & Alloys | Sehlopha se Tsebahalang |

| Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Tšepe ea ho Rala ea Ductile (Nodular). | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Tšepe ea Carbon | C20, C25, C30, C45 |

| Alloy Steel | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Ts'epe e sa beng le mabali | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Pula e thatafatsa Stainless Steel, Duplex Stainless Steel |

| Lisebelisoa tsa Aluminium | ASTM A356, ASTM A413, ASTM A360 |

| Lisebelisoa tsa koporo / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, le GB | |

Melemo ea Furan Resin Coated Coated Sanding Molding Casting:

1) Ntlafatsa ho nepahala ha dimensional tsa castings le bokaholimo ba bokaholimo.

2) Ho thatafala ha hlobo (konokono) lehlabathe ha ho hloke ho omisoa, ho ka bolokang matla, 'me lehong le theko e tlaase kapa mabokose a motheo a polasetiki le li-templates le tsona li ka sebelisoa.

3) Lehlabathe le ithatang le le thata le bonolo ho kopana le ho putlama, ho bonolo ho hloekisa li-castings, 'me lehlabathe la khale le ka sebelisoa hape le ho sebelisoa hape, e leng ho fokotsang matla a mosebetsi oa ho etsa mantlha, ho etsa mohlala, ho oela lehlabathe, ho hloekisa le lihokelo tse ling, le ho bonolo ho elelloa ts'ebetso kapa boiketsetso.

4) Karolo e kholo ea resin lehlabatheng ke 0.8% ~ 2.0% feela, mme litšenyehelo tse felletseng tsa lisebelisoa tse tala li tlase.

Hobane mokhoa oa ho ithatafatsa o na le melemo e mengata e ikhethang e boletsoeng ka holimo, mokhoa oa ho ithatafatsa ha o sebelisoe feela bakeng sa ho etsa li-core, empa o boetse o sebelisetsoa ho lahla ho bōpa. E loketse ka ho khetheha bakeng sa tlhahiso e le 'ngoe le lihlahisoa tse nyenyane,' me e ka hlahisa tšepe e entsoeng ka tšepe, tšepe e entsoeng ka tšepe le li-alloy castings tse se nang ferrous. Mehaho e meng ea Machaena e nkile sebaka ka ho felletseng liforomo tsa lehlabathe le omeletseng la letsopa, liforomo tsa lehlabathe la samente, 'me ka mokhoa o sa fellang li nketse hlobo ea lehlabathe la khalase ea metsi.

Lihlahisoa tsa tšepe tsa ductile Cast